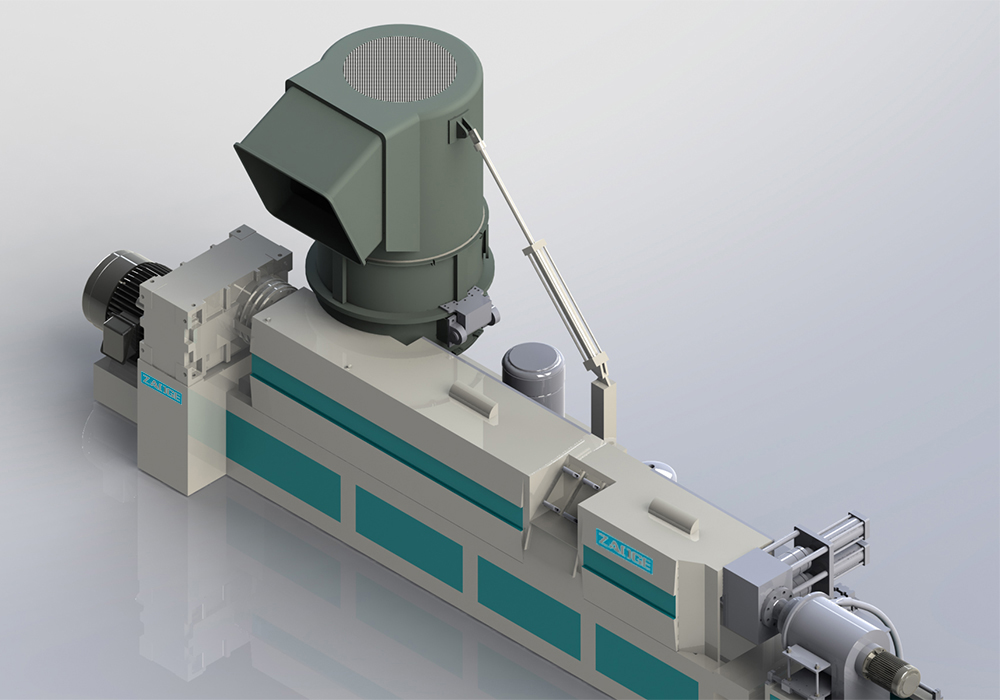

Three-In-One Plastic Granulators

Description

This equipment is suitable for PP, OPP, BOPP, HDPE, LDPE, LLDPE, ABS, HIPS and other plastic environmental protection Granulators. Adopting a German reducer motor, effective power saving up to 20%; three machines in one crushing, extruding, and Plastic Granulators, die cutting without water tank device, less space for setting; adopting non-stop double column hydraulic screen changing, simple and convenient operation, which is conducive to improving operation efficiency and production capacity.

Description

This equipment is suitable for PP, OPP, BOPP, HDPE, LDPE, LLDPE, ABS, HIPS and other plastic environmental protection pelletizing. Adopting German reducer motor, effective power saving up to 20%; three machines in one crushing, extruding and pelletizing, die cutting without water tank device, less space for setting; adopting non-stop double column hydraulic screen changing, simple and convenient operation, which is conducive to improving operation efficiency and production capacity.

More Details

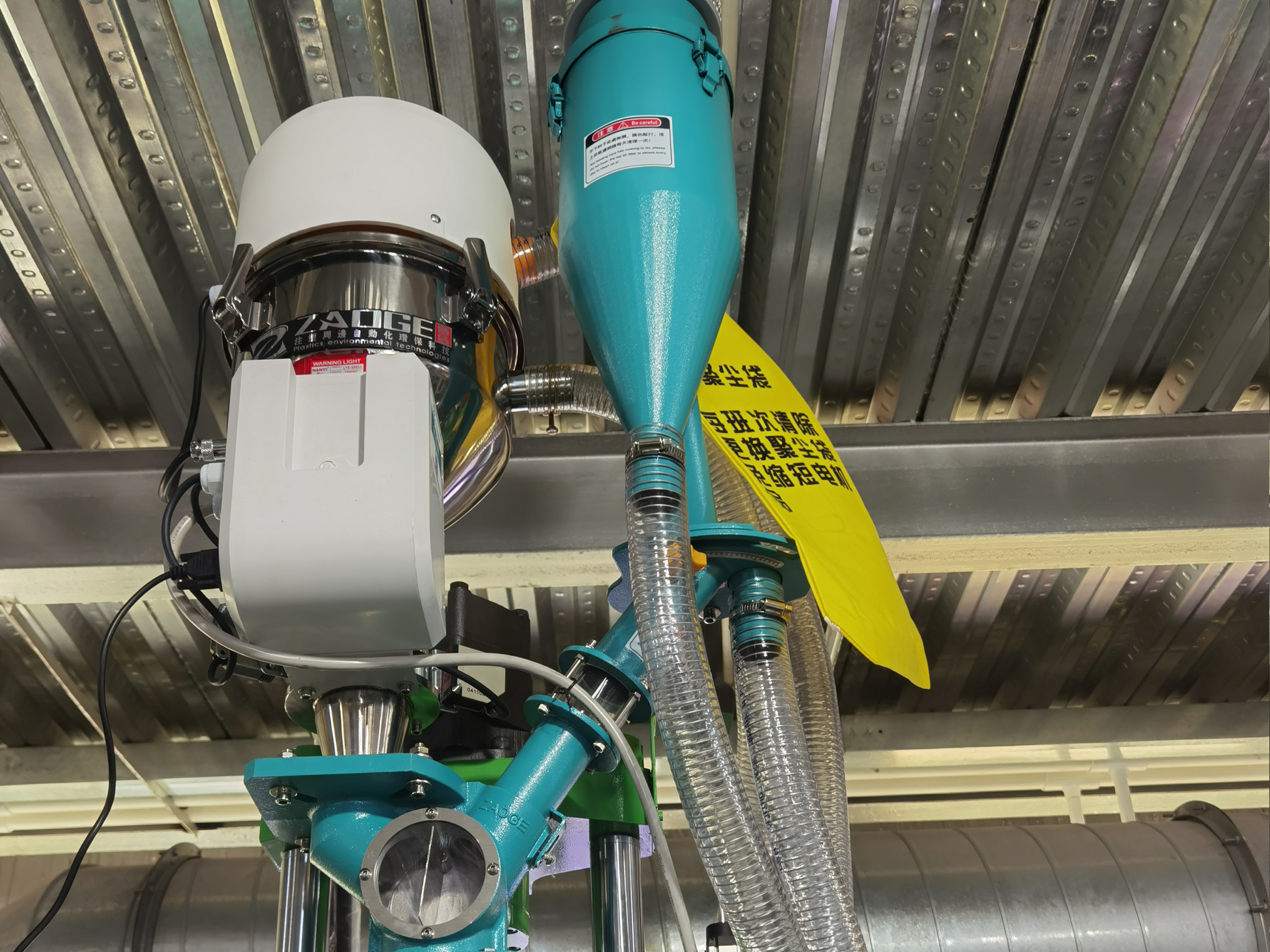

Vent Hole

The water and waste gas in the raw materials are discharged through the vent hole, which enables the production of higher-quality plastic pellets during extrusion. A vacuum suction system is also available as an optional feature.

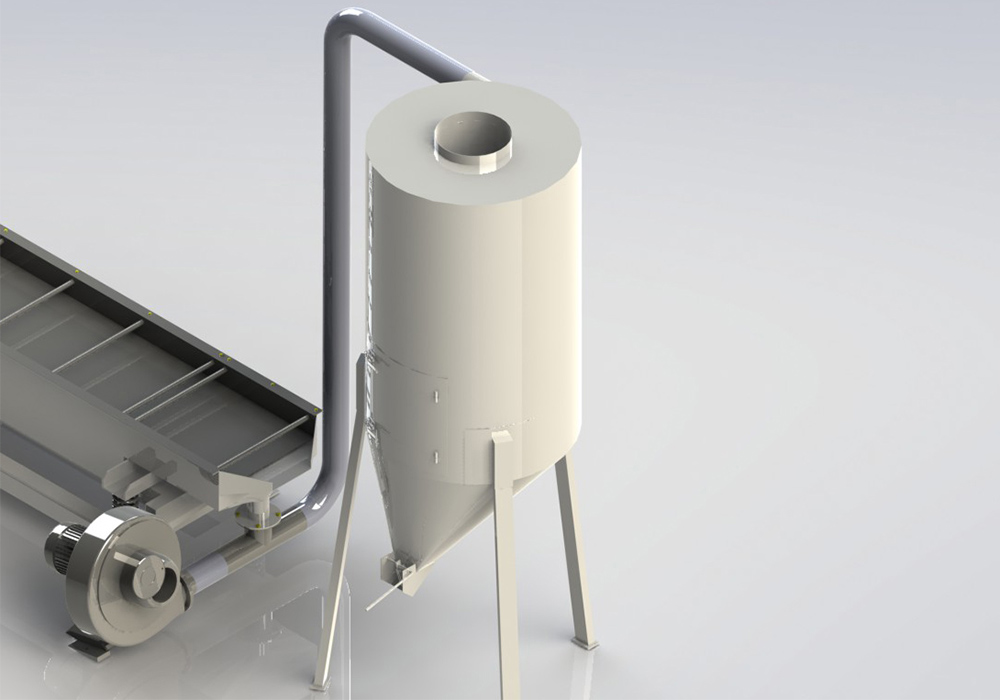

Dehydrator

Plastic particles, together with the cooling water from the cutting cooling tank at the die head, enter the bottom inlet of the dehydrator. Through the specially designed centrifugal blades and screens inside the dehydrator, residual water on the particles can be completely removed.

Dehydrator

Plastic particles, together with the cooling water from the cutting cooling tank at the die head, enter the bottom inlet of the dehydrator. Through the specially designed centrifugal blades and screens inside the dehydrator, residual water on the particles can be completely removed.

Crushing Bucket

Changyi Machinery's system crushes films and edge materials from blown film factories, generating heat that dries moist materials. It has automatic water sprinklers to cool it down and a water cooling system to prevent clumping when changing blades.

Die Face Plastic Granulators System

Molten plastic is extruded from the die head and cut by rotating blades before falling into a water ring for cooling. The system has an automatic correction blade holder design for more uniform particles.

Die Face Plastic Granulators System

Molten plastic is extruded from the die head and cut by rotating blades before falling into a water ring for cooling. The system has an automatic correction blade holder design for more uniform particles.

Granulator’s Applications

Plastic Fiber

Hdpe Plastic Bags

Non-Woven Fabric

Zipper

Film

Foam

Specifications

|

ZGL series |

|||||||

|

Mode |

ZGL-65 |

ZGL-85 |

ZGL-100 |

ZGL-125 |

ZGL-135 |

ZGL-155 |

ZGL-175 |

|

Crushing moter power |

30HP |

60HP |

70HP |

100HP |

125HP |

175HP |

200HP |

|

Host moter power |

75HP |

75HP |

125HP |

175HP |

200HP |

250HP |

350HP |

|

Temperature control point |

6 components (4 material pipes, 1 screen changer, and 1 discharge) |

6 components (4 material pipes, 1 screen changer, and 1 discharge) |

6 components (4 material pipes, 1 screen changer, and 1 discharge) |

8 components (6 material pipes, 1 screen changer, and 1 discharge) |

8 components (6 material pipes, 1 screen changer, and 1 discharge) |

10 components (8 material pipes, 1 screen changer, and 1 discharge) |

10 components (8 material pipes, 1 screen changer, and 1 discharge) |

|

Capacity |

80~100kg/h |

200~300kg/h |

300~400kg/h |

450~600kg/h |

550~700kg/h |

700~800kg/h |

800~1000kg/h |

|

material pipe cooling system |

Fan Cooling |

Fan Cooling |

Fan Cooling |

Fan Cooling |

Fan Cooling |

Fan Cooling |

Fan Cooling |