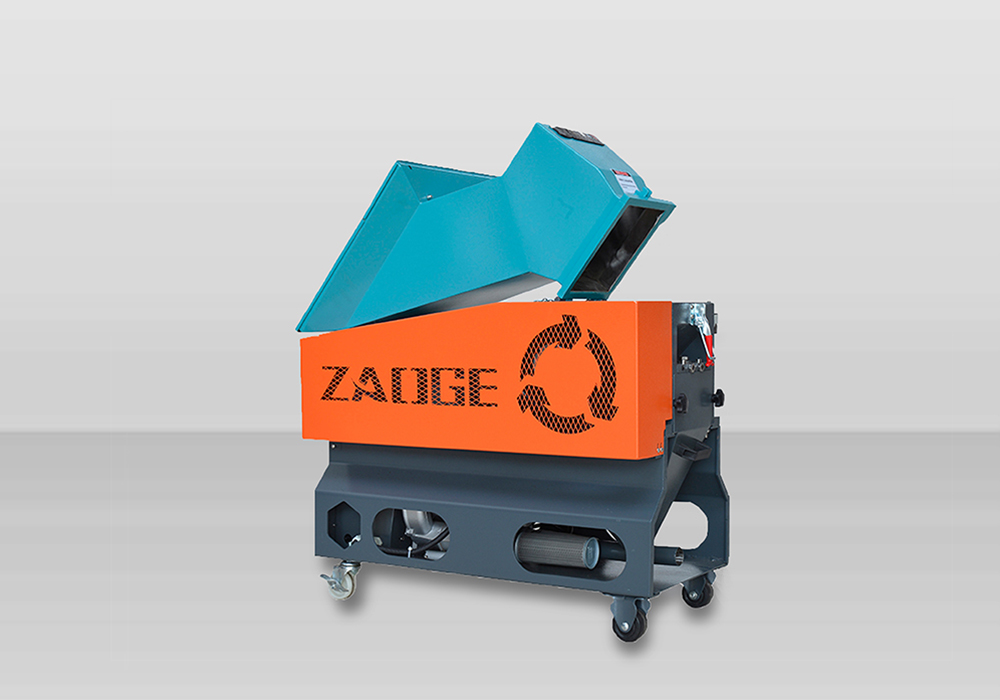

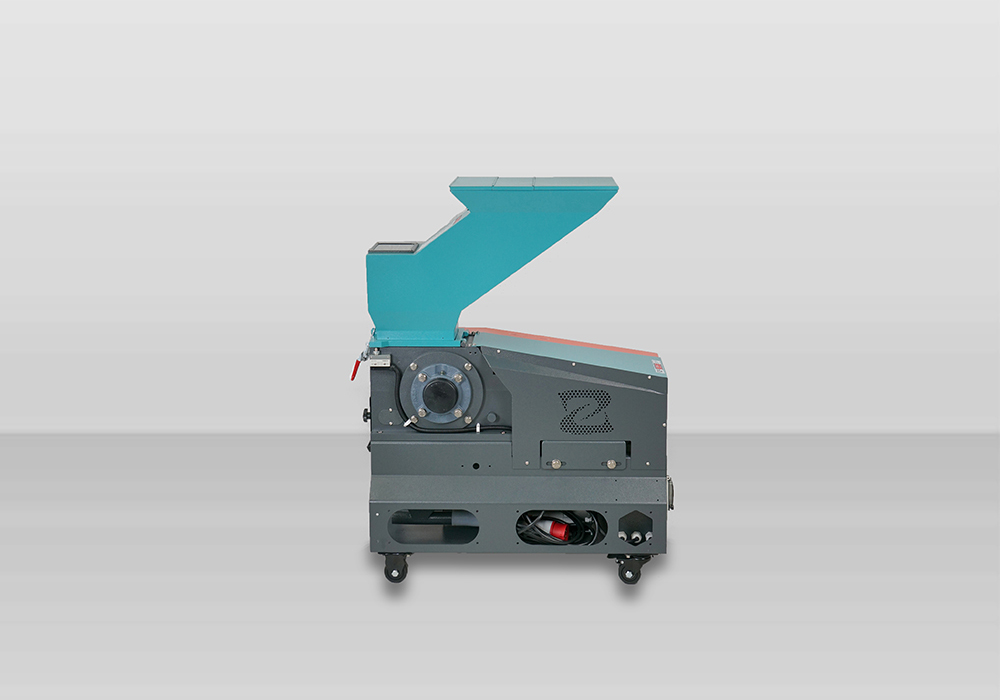

Silent Plastic Recycling Shredder

Description

"The Silent Plastic Recycling Shredder is suitable for crushing soft sprue materials such as halogen-free, PVC, PP, PE, TPR, etc. For example, plastic injection molding sprue materials such as power cord plugs, data cables, and cable extrusions.

With the "V" shaped blade, the cutting of materials is more uniform. It is noise-free, screw-free, and has a precision-integrated casting design, making it easier and faster to change colors and materials. The equipment adopts Taiwanese motor and controller components, which have low power consumption, long lifespan, and ensure stable and safe operation. It can save about 600USD of electricity per year for every 0.75kw of power. The transmission device uses European standard pulleys that have been statically and dynamically balanced, making the operation smoother and the replacement simpler."

Description

"The Silent Plastic Recycling Shredder is suitable for crushing soft sprue materials such as halogen-free, PVC, PP, PE, TPR, etc. For example, plastic injection molding sprue materials such as power cord plugs, data cables, and cable extrusions.

With the "V" shaped blade, the cutting of materials is more uniform. It is noise-free, screw-free, and has a precision-integrated casting design, making it easier and faster to change colors and materials. The equipment adopts Taiwanese motor and controller components, which have low power consumption, long lifespan, and ensure stable and safe operation. It can save about 600USD of electricity per year for every 0.75kw of power. The transmission device uses European standard pulleys that have been statically and dynamically balanced, making the operation smoother and the replacement simpler."

More Details

Crushing cavity

open structure design, easy for operation and cleaning, precision gravity casting, thickness of 30mm, ensuring the surface smoothness and dimensional accuracy of the crushing cavity, more durable and quieter, V-type knife without screws design, cutting material more uniformly, reducing noise during the crushing process, and facilitating color and material changeover.

Knife Material

The blade is made of high-quality NACHI blade material from Japan, and is processed using CNC precision machining and German imported vacuum heat treatment equipment for ultra-high and ultra-low temperature processing. This ensures high wear resistance and longer service life for the blade.

Knife Material

The blade is made of high-quality NACHI blade material from Japan, and is processed using CNC precision machining and German imported vacuum heat treatment equipment for ultra-high and ultra-low temperature processing. This ensures high wear resistance and longer service life for the blade.

Motor, Electric Control

The motor and control components are sourced from Siemens, Taiwan Dongyuan , and Dongguan , with Siemens and Taiwan Dongyuan providing the control components. The use of these components results in lower power consumption, making them safer and more stable for use.

Fasteners, Sheet Metal Component

The use of stainless steel screws and spray-painting technology ensures that the color is more durable, and less likely to rust or fade.

Fasteners, Sheet Metal Component

The use of stainless steel screws and spray-painting technology ensures that the color is more durable, and less likely to rust or fade.

Plastic Recycling Shredder Applications

AC Power Supply Injection Molding

Automotive Parts Injection Molding

DC Power Cord/Data Cable Injection Molding

Fitness and Medical Molding

PVCTPUTPE Rubber Wire Calendering

Silicone Rubber Material

Stationery Blow Molding

TPRTPETPUPVC Electronic and Consumer Products

Specifications

|

ZGS series |

|||

|

Mode |

ZGS-718/738 |

ZGS-818/838 |

ZGS-918/938 |

|

Motor Power |

0.75KW |

1.5KW |

2.2KW |

|

Cutting Chamber |

165x210mm |

210x210mm |

270x210mm |

|

Raotating Speed |

300rpm |

300rpm |

300rpm |

|

Max.Output Capacity |

10-20Kg/h |

20-30Kg/h |

30-50Kg/h |

|

Weight |

210Kg |

260Kg |

320Kg |

|

Dimensions L*W*H mm |

850*450*950 |

850*550*950 |

850*650*950 |

|

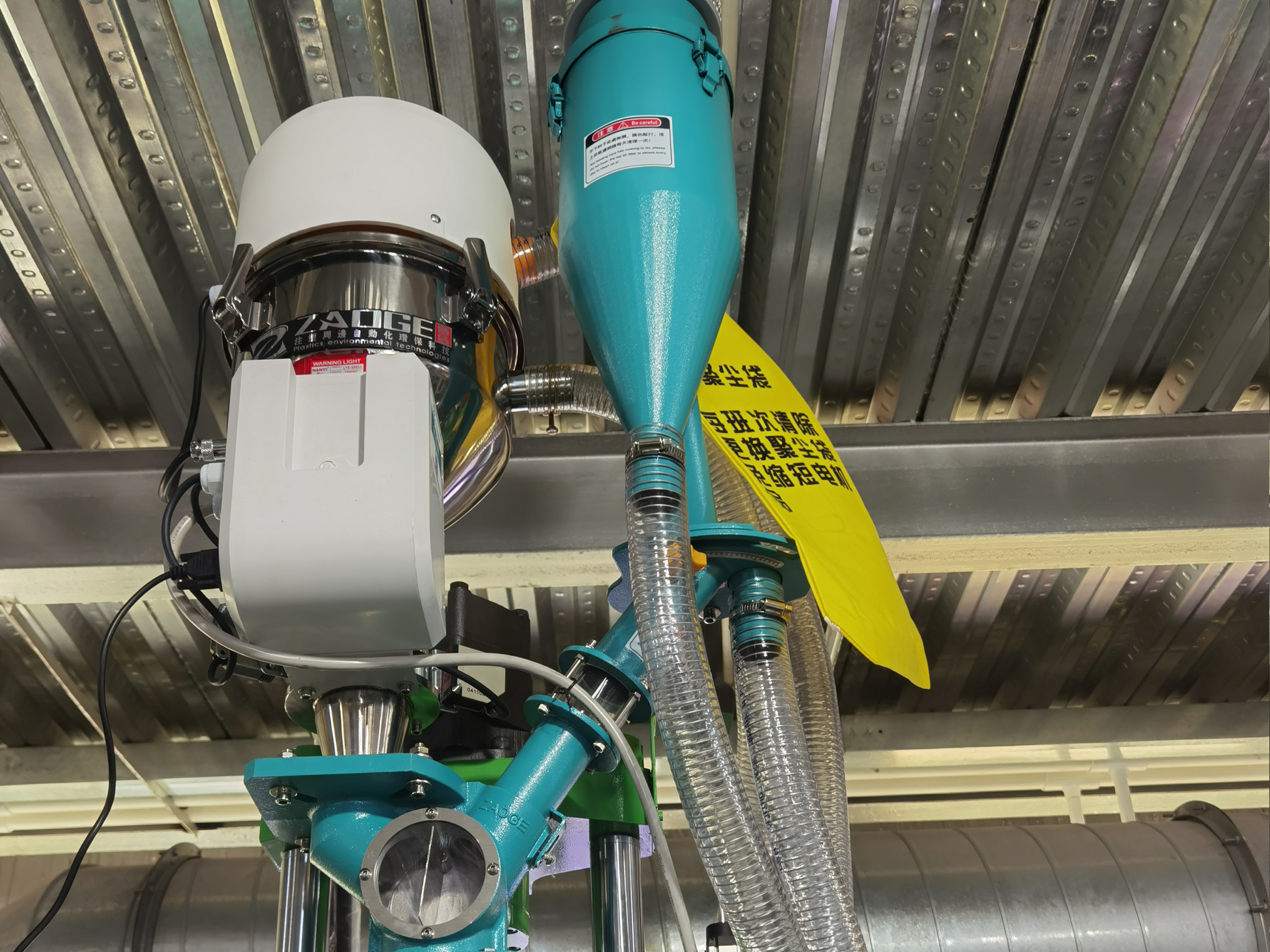

Optional parts |

400W Conveyor fan,Sieve Powder Cyclone Separator,Electrostatic output tube,Proportional smooth tube,Three fork mixed packing seat. | ||