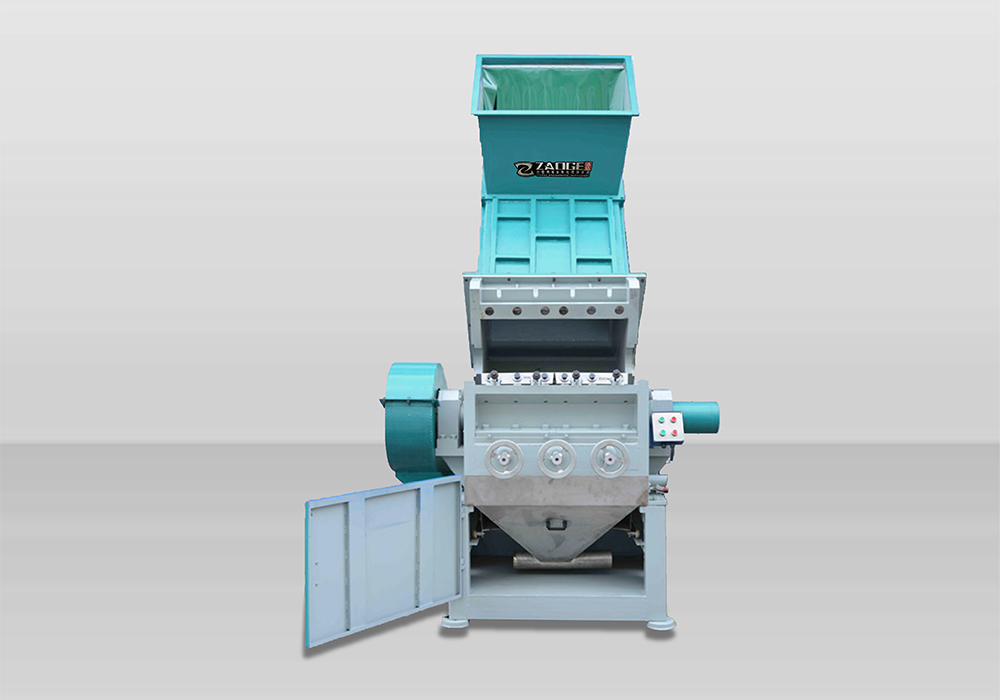

Powerful Plastic Crusher machine

Description

The Powerful Plastic Crusher is suitable for centralized crushing of defective products, pipes, profiles, sheets, containers, electrical housings, automotive parts, and other injection-molded or extruded materials.

The thickness of the crushing chamber is 40mm, which provides better sound insulation and wear resistance. The hydraulic device can be opened and closed more safely and reliably. The cutting tools are made of Japanese NACHI material and feature a seven-blade design, which makes cutting smoother, operation more stable, and crushing particles more uniform. The heavy-duty rotor bearing is externally mounted to better protect the crushing chamber and cutting tools. The power system adopts a Dongguan motor, and the control components are Siemens or Taiwan Dongyuan, reducing power consumption, prolonging service life, and providing greater stability and safety.

Description

The Powerful Plastic Crusher is suitable for centralized crushing of defective products, pipes, profiles, sheets, containers, electrical housings, automotive parts, and other injection-molded or extruded materials.

The thickness of the crushing chamber is 40mm, which provides better sound insulation and wear resistance. The hydraulic device can be opened and closed more safely and reliably. The cutting tools are made of Japanese NACHI material and feature a seven-blade design, which makes cutting smoother, operation more stable, and crushing particles more uniform. The heavy-duty rotor bearing is externally mounted to better protect the crushing chamber and cutting tools. The power system adopts Dongguan motor, and the control components are Siemens or Taiwan Dongyuan, reducing power consumption, prolonging service life, and providing greater stability and safety.

More Details

Crushing Chamber

The crushing chamber is made of strong and durable cast steel that is precisely machined using CNC technology. Its 40mm thickness guarantees a smooth surface that reduces friction and wear, resulting in a longer lifespan, higher efficiency, and safer operation.

Unique Cutting Tools

The design of claw blades can improve cutting efficiency and reduce thermal deformation of materials. The blades are made of imported SKD-11 material, ensuring cutting efficiency, durability, and extended lifespan.

Unique Cutting Tools

The design of claw blades can improve cutting efficiency and reduce thermal deformation of materials. The blades are made of imported SKD-11 material, ensuring cutting efficiency, durability, and extended lifespan.

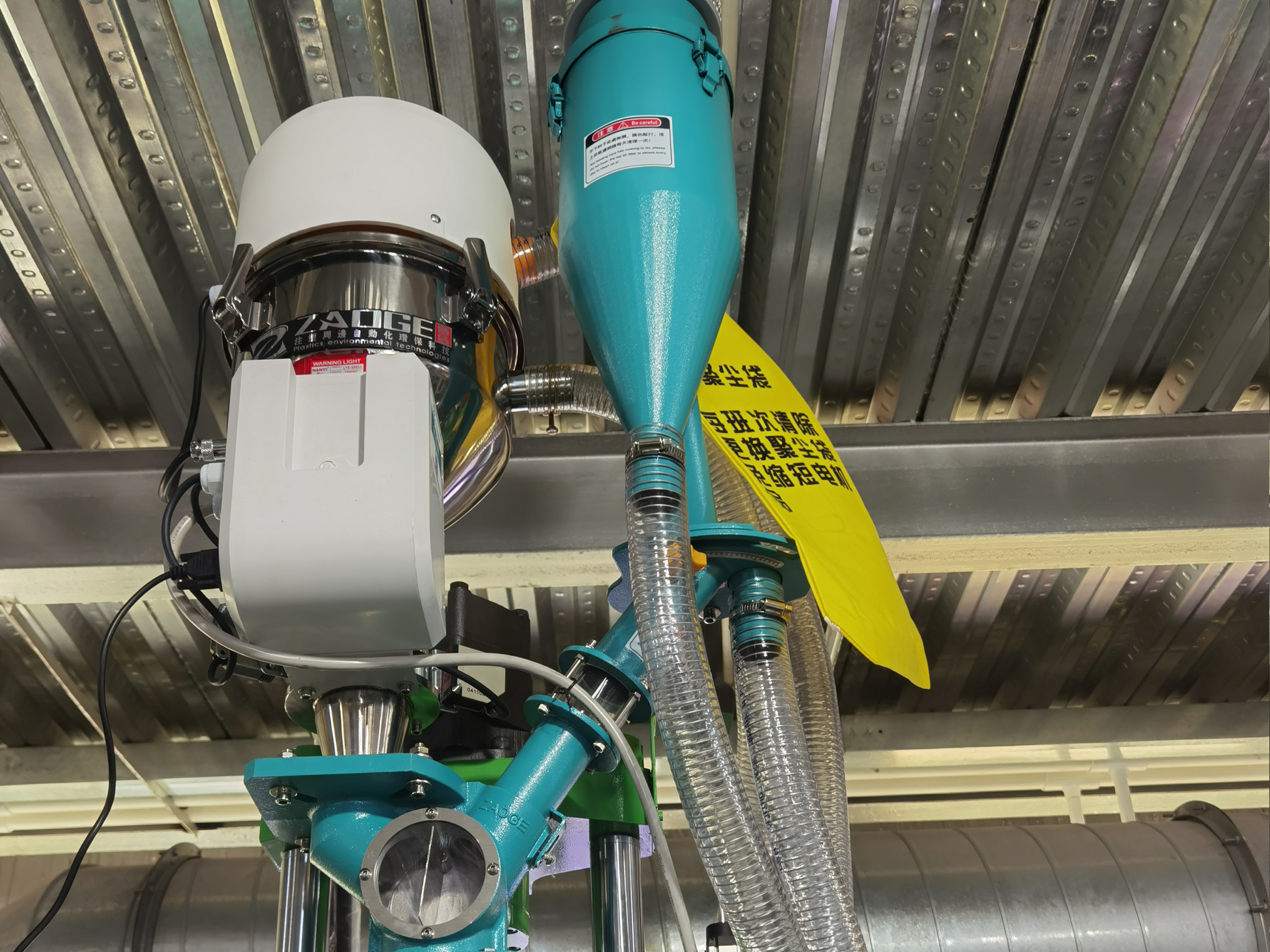

Transmission Device

Using external bearings in the design can prevent impurities and dirt from entering the bearings, reducing wear and extending their lifespan. It also makes maintenance easier and improves transmission efficiency and stability.

Power System

Cutting machines equipped with Dongguan/Siemens motors and Siemens/Schneider electric control systems offer high efficiency, stability, safety, and ease of maintenance. This results in improved production efficiency, product quality, and safety performance, while also reducing failure rates and maintenance costs, and extending the lifespan of the machine.

Power System

Cutting machines equipped with Dongguan/Siemens motors and Siemens/Schneider electric control systems offer high efficiency, stability, safety, and ease of maintenance. This results in improved production efficiency, product quality, and safety performance, while also reducing failure rates and maintenance costs, and extending the lifespan of the machine.

Plastic Crusher Applications

AC Power Supply Injection Molding

Automotive Parts Injection Molding

Silicone Rubber Material

Medical Injection Molded Products

Injection Molded for Helmets and Suitcases

Communications Electronics Products

Cosmetic Bottleswatering Cansplastic Condiment Bottles

Household Electrical Appliances

Specifications

|

ZGP series |

||||||||||

|

Mode |

ZGP-530 |

ZGP-560 |

ZGP-580 |

ZGP-640 |

ZGP-680 |

ZGP-690 |

ZGP-730 |

ZGP-750 |

ZGP-770 |

ZGP-790 |

|

Motor Power |

7.5KW |

15KW |

22KW |

22KW |

30KW |

37KW |

37KW |

45KW |

45KW |

75KW |

|

Rotary diameter |

300mm |

300mm |

300mm |

400mm |

400mm |

400mm |

500mm |

500mm |

600mm |

600mm |

|

Fixed blades |

2*1PCS |

2*1PCS |

2*2PCS |

3*1PCS |

3*2PCS |

3*2PCS |

3*2PCS |

3*2PCS |

3*2PCS |

3*2PCS |

|

Rotating blades |

3*1PCS |

3*2PCS |

3*2PCS |

3*2PCS |

3*2PCS |

3*2PCS |

5*2PCS |

5*2PCS |

5*2PCS |

5*2PCS |

|

Cutting Chamber |

370*300mm |

370*585m |

370*785mm |

490*600mm |

490*800mm |

490*1000mm |

600*800mm |

600*1000mm |

740*800mm |

740*1100mm |

|

Screen |

Φ10 |

Φ10 |

Φ10 |

Φ10 |

Φ10 |

Φ10 |

Φ10 |

Φ10 |

Φ12 |

Φ12 |

|

Weight |

850Kg |

1100Kg |

1500Kg |

2500Kg |

2800Kg |

3200Kg |

3800Kg |

4200Kg |

4000Kg |

6100Kg |

|

Dimensions L*W*H mm |

1350*700*1800 |

1350*1000*1850 |

1350*1300*1850 |

1700*1350*2250 |

2100*1550*2500 |

2100*1800*2500 |

2300*1800*2900 |

2300*2000*2900 |

2600*1800*3300 |

2600*2200*3300 |