Industrial Vacuum Conveyors for Sale

Description

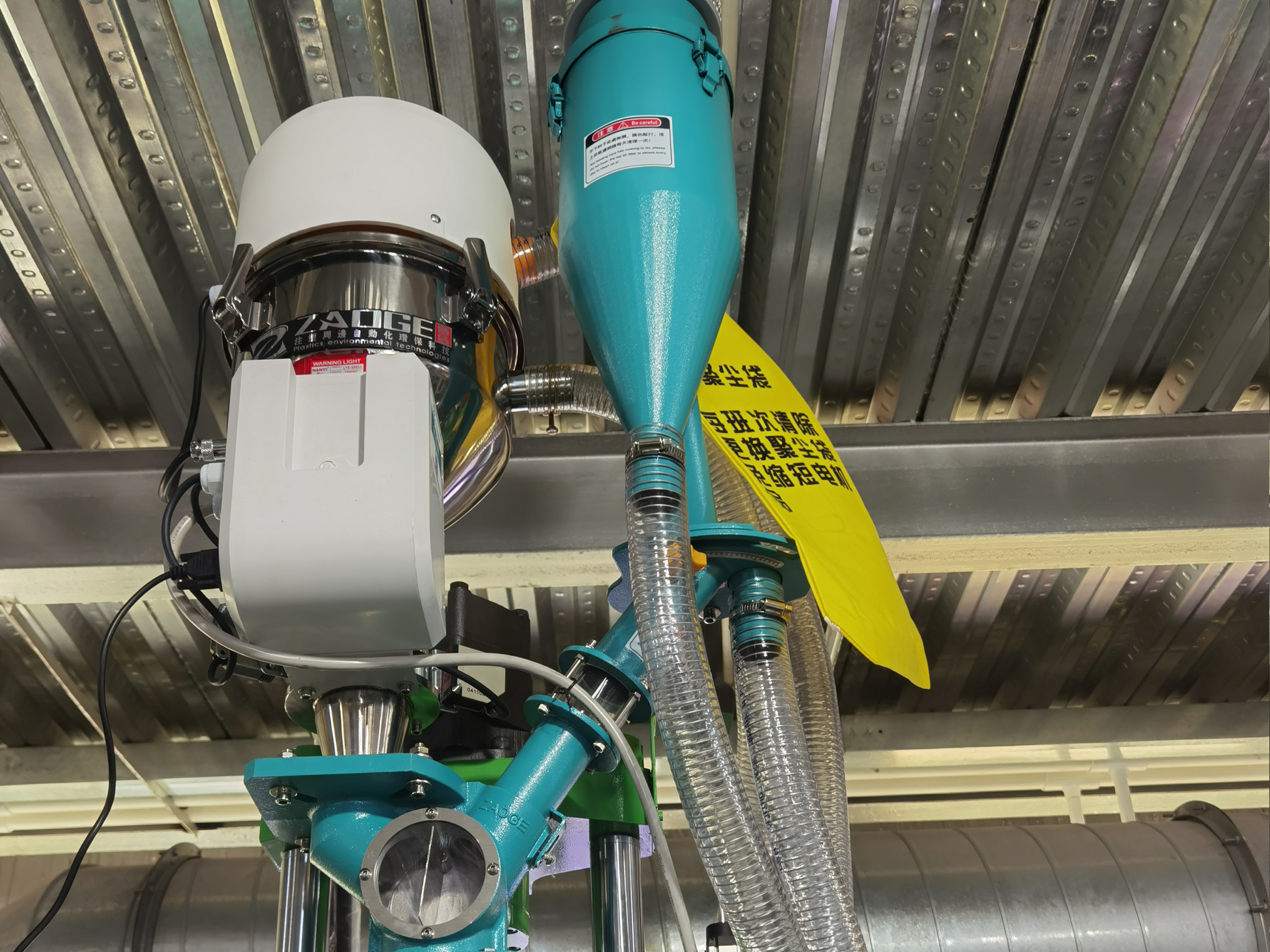

This product is characterized by its small size, easy mobility, and convenient installation. It features a wired controller for easy operation, motor start protection, carbon brush fault and usage time reminders, and adjustable hopper and base for versatile use. It also comes with a differential pressure switch and filter clogging alarm function for improved safety, as well as an automatic cleaning device to reduce manual cleaning frequency and increase efficiency. Overall, this product is a versatile and efficient drying equipment suitable for various scenarios and needs.

Description

This product is characterized by its small size, easy mobility, and convenient installation. It features a wired controller for easy operation, motor start protection, carbon brush fault and usage time reminders, and adjustable hopper and base for versatile use. It also comes with a differential pressure switch and filter clogging alarm function for improved safety, as well as an automatic cleaning device to reduce manual cleaning frequency and increase efficiency. Overall, this product is a versatile and efficient drying equipment suitable for various scenarios and needs.

More Details

Motor

The Ametek motor in the direct suction unit is a reliable three-phase motor with a fan, ranging from 1.5 kW to 15 kW. It has excellent durability and moisture resistance, and the fan helps improve efficiency and lifespan. It requires regular maintenance and safety protection features such as overload and overheat protection to ensure proper operation and safety.

Circuit Board

The circuit board is a crucial component in the direct suction unit for controlling and monitoring equipment operation. It employs surface mount technology for compactness and safety protection features such as overcurrent, overvoltage, and short circuit protection. Regular maintenance, including cleaning and moisture prevention, is necessary to ensure proper operation and prolong service life.

Circuit Board

The circuit board is a crucial component in the direct suction unit for controlling and monitoring equipment operation. It employs surface mount technology for compactness and safety protection features such as overcurrent, overvoltage, and short circuit protection. Regular maintenance, including cleaning and moisture prevention, is necessary to ensure proper operation and prolong service life.

Stainless Steel Bucket

The stainless steel hopper is a crucial part of the direct suction unit, used for storing or conveying powdery or granular materials. It is made of high-quality stainless steel and designed with safety features, an inlet, and a vent to ensure material quality and stability. Regular cleaning and disinfection are necessary to maintain its hygiene and quality.

Sealing Process

The sealing technology of the direct suction unit is crucial to prevent material leakage and air pollution. It employs a double-layer sealing structure and requires pressure and vacuum testing to ensure quality. Regular maintenance, including inspection and replacement of sealing components, and applying sealant, is necessary to ensure proper operation and material quality.

Sealing Process

The sealing technology of the direct suction unit is crucial to prevent material leakage and air pollution. It employs a double-layer sealing structure and requires pressure and vacuum testing to ensure quality. Regular maintenance, including inspection and replacement of sealing components, and applying sealant, is necessary to ensure proper operation and material quality.

Loader’s Applications

Automotive Parts Injection Molding

Communications Electronics Products

DC Power Cord/Data Cable Injection Molding

Fitness and Medical Molding

Household Electrical Appliances

Stationery Blow Molding

Specifications

|

Mode |

ZGY-300G |

ZGY-300GD |

ZGY-400G |

ZGY -700G |

ZGY -800G1 |

ZGY -800G2 |

ZGY -800G3 |

ZGY-900G1 OPEN |

ZGY-900G2OPEN |

ZGY -900G3OPEN |

ZGY -900G4OPEN |

ZGY -900G5OPEN |

|

|

Motor |

Type |

carbon brush type |

carbon brush type |

induction type |

carbon brush type |

induction type |

induction type |

induction type |

induction type |

induction type |

induction type |

induction type |

induction type |

|

Specifhcation |

220V /single-phase/ 1.5P | 220V /single-phase/ 1.5P | 380V /three-phase/ 1P | 220V /single-phase/ 1.5P | 380/ three-phase/ 1.5P | 380/ three-phase 2P | 380/ three-phase/ 3P | 380/ three-phase/ 1.5P | 380/ three-phase/ 2P | 380/ three-phase/ 3P | 380/ three-phase/4P | 380/ three-phase/5P | |

|

motor power |

1.1KW |

1.1KW |

0.75KW |

1.1KW |

1.1KW |

1.5kw |

2.2kw |

1.5kw |

2.2kw |

3kw |

3.8kw |

5.5kw |

|

| feeding capacity |

350kg/h |

350kg/h |

400kg/h |

400kg/h |

400kg/h |

550kg/h |

700kg/h |

400kg/h |

550kg/h |

700kg/h |

700kg/h |

800kg/h |

|

|

Suction |

4m |

4m |

4m |

4m |

4m |

4m |

4m |

4m |

4m |

4m |

5m |

5m |

|

| static pressure (mm/h20) |

1500 |

1500 |

1800 |

1500 |

1500 |

2200 |

2500 |

1800 |

2200 |

2500 |

2500 |

2500 |

|

| storage bin capacity |

7.5L |

7.5L |

7.5L |

7.5L |

7.5L |

7.5L |

7.5L |

7.5L |

7.5L |

12L |

12L |

25L |

|

|

dimensions for hopper base installation/MM |

18*18 |

18*18 |

18*18 |

18*18 |

18*18 |

18*18 |

18*18 |

18*18 |

18*18 |

18*18 |

18*18 |

18*18 |

|

|

inner diameter of the delivery pipe |

38mm |

38mm |

38mm |

38mm |

38mm |

38mm |

38mm |

38mm |

38mm |

38mm |

38mm/51mm |

38mm/51mm |

|

|

Size (mm) |

Main Machine |

206x330x545 |

206x330x565 |

206x330x670 |

365x295x540 |

365x295x540 |

445x375x625 |

445x375x625 |

420x470x1080 |

420x470x1080 |

420x470x1080 |

420x470x1080 |

420x470x1080 |

|

Package |

370x360x640 |

370x360x680 |

430x440x730 |

700x340x580 |

700x340x580 |

740x410x710 |

740x410x710 |

480x520x1200 |

480x520x1200 |

480x520x1200 |

480x520x1200 |

480x520x1200 |

|

|

Weight |

14kg |

18kg |

26kg |

25kg |

35KG |

40KG |

45kg |

55kg |

60kg |

65kg |

75kg |

80kg |

|