Film Plastic Recycling Shredder

Description

This Film Plastic Recycling Shredder is suitable for grinding various soft and hard edge materials with a thickness of 0.02~5MM, such as PP/PE/PVC/PS/GPPS/PMMA films, sheets, and plates used in stationery, packaging, and other industries.

It can be used to collect, crush and convey the edge materials produced by extruders, laminators, sheet machines, and plate machines. The crushed materials are then transported by a conveying fan through a pipeline to a cyclone separator, and then pushed into the extruder screw feed port by a feeding screw for automatic mixing with new materials, thus achieving instant environmental protection and utilization.

Description

This Film Plastic Recycling Shredder is suitable for grinding various soft and hard edge materials with a thickness of 0.02~5MM, such as PP/PE/PVC/PS/GPPS/PMMA films, sheets, and plates used in stationery, packaging, and other industries.

It can be used to collect, crush and convey the edge materials produced by extruders, laminators, sheet machines, and plate machines. The crushed materials are then transported by a conveying fan through a pipeline to a cyclone separator, and then pushed into the extruder screw feed port by a feeding screw for automatic mixing with new materials, thus achieving instant environmental protection and utilization.

More Details

Crushing Structure

The feeding port is equipped with a traction device and adjustable speed, which enables smooth traction of edge materials such as thin films and sheets to the crushing machine feeding port, ensuring a uniform and steady crushing process.

Unique Blades

The machine features a unique design with five oblique cutting blades, providing more powerful cutting capabilities. The imported SKD-11 blades are highly wear-resistant and durable, ensuring more uniform cutting of materials.

Unique Blades

The machine features a unique design with five oblique cutting blades, providing more powerful cutting capabilities. The imported SKD-11 blades are highly wear-resistant and durable, ensuring more uniform cutting of materials.

Power System

The machine utilizes Siemens or Taiwan Wanxin's reduction motor, which results in more stable, energy-efficient, and safe operation. It also provides better protection for the machine equipment and operators.

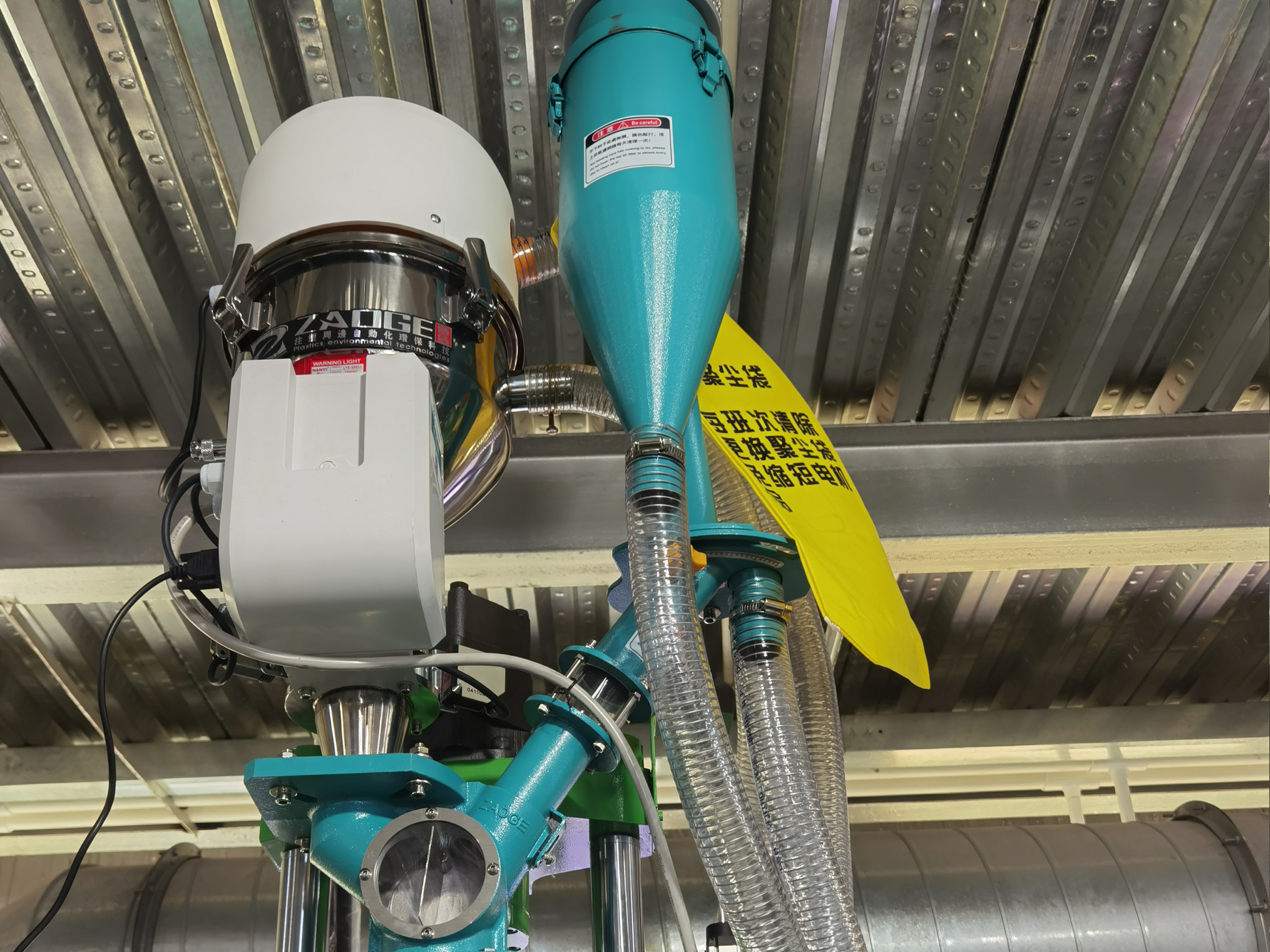

Conveying System

The conveying blower is designed with dynamic balancing and a double-layer structure, resulting in minimal vibration, less noise, and longer conveying distance. The discharging port adopts a screw pushing method, ensuring a smoother and more uniform feeding process.

Conveying System

The conveying blower is designed with dynamic balancing and a double-layer structure, resulting in minimal vibration, less noise, and longer conveying distance. The discharging port adopts a screw pushing method, ensuring a smoother and more uniform feeding process.

Plastic Recycling Shredder Applications

Agricultural Film

Cigarette Box Stretch Film

Mobile Phone

Tablet Tempered Film

Packaging Film

Protective Film

Sealing Film

Sheet Molding

Stationery

Specifications

|

ZGS2 series |

||

|

Mode |

ZGS-255 |

ZGS-270 |

|

Motor Power |

2.2KW |

4KW |

|

Rotary diameter |

180mm |

230mm |

|

Fixed blades |

2PCS |

2PCS |

|

Rotating blades |

3PCS |

3PCS |

|

Conveyor fan motor power |

2.2KW |

2.2KW |

|

Motor power of screw conveyor |

0.75KW |

0.75KW |

|

Pull wheels width |

100~150mm |

150~280mm |

|

Motor power of pulley wheels |

0.75KW |

0.75KW |

|

Screen |

8MM |

8MM |

|

Capacity |

30~60Kg/h |

50~120Kg/h |

|

Weight |

350Kg |

420Kg |

|

Dimensions L*W*H mm |

1200*900*1100 |

1400*1000*1300 |