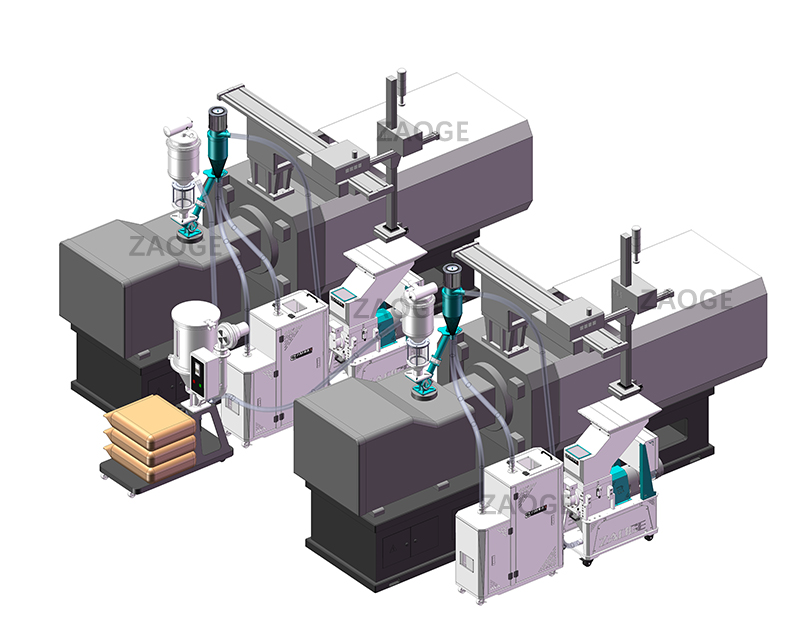

The injection molding process in the electronic connector industry often produces a large amount of sprues. These sprues not only occupy space but also cause waste to resource utilization and the environment. To solve this problem, slow crushing and recycling machines came into being. Slow-crushing recycling machine in the electronic connector industry has a wide range of applications in the treatment of sprues, similar to PBT, PC, LCP, PP, and other materials, computer connector sprues, first of all, can efficiently crush the sprues, sieve out the dust and the automatic fixed-ratio mixing, and then directly transported to the screw to utilize the right away to reduce the cost of raw material procurement, improve production efficiency, reduce labor costs, improve product quality stability and reliability, and improve product quality and reliability. It also improves the stability and reliability of product quality.

Zaoge Crusher, as a leading supplier in the electronic connector industry, is committed to providing our customers with high-quality Slow Shredding Recycling Machines. Zaoge crusher's equipment is carefully designed and optimized for reliable performance and long-lasting durability. We also offer customized solutions with equipment configuration and technical support according to customer needs.

Client Testimonials

More than 60% durable compared to the same period of time, saving effort and money

Featured Products

No noise: noise as low as 50dB

Convenient cleaning: coarse and fine crushing synchronization

Ultra-durable: trouble-free service life of up to 5~20 years.

Environmental protection: energy saving, reduce consumption

Material Comparison

Good quality comes from every detail

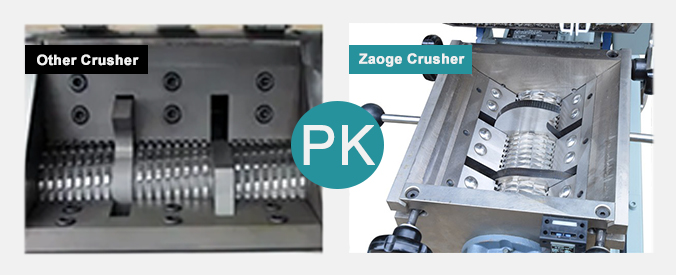

Slow Speed Crusher · Crushing Chamber

The open design of the crushing chamber allows for easy color and material changeovers and cleaning. With a thickness of 25mm, it provides a quieter operation and enhanced durability.

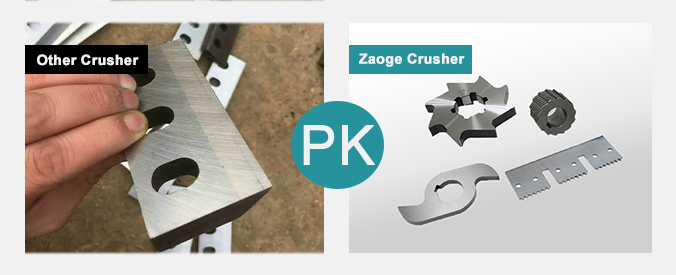

Slow Speed Crusher · Imported Blade Material

The blade material used, sourced from Japan's NACHI, undergoes CNC precision processing and ultra-high/ultra-low temperature treatment using German-imported vacuum heat treatment equipment, ensuring excellent wear resistance.

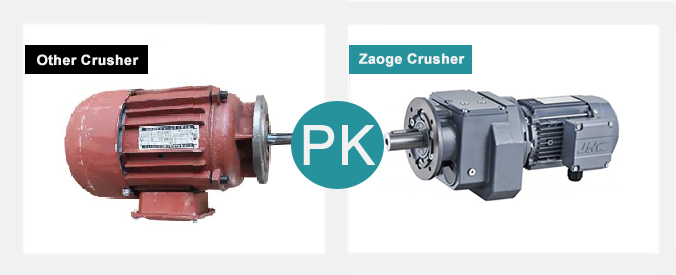

Slow Speed Crusher · Transmission Control

Taiwan Dongyuan/Siemens motors are employed, characterized by low energy consumption. They effectively reduce energy consumption, helping users save costs and minimize environmental impact.

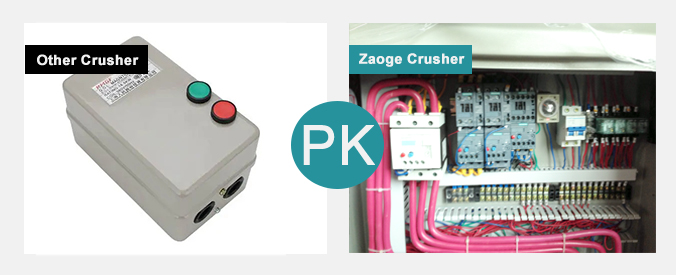

Slow Speed Crusher · Control Box

Imported Taiwan Dongyuan/Siemens controller provides better protection, convenient operation, and increased safety for users.

FAQ

We are a Manufacturer located in Dongguan, China. Specialized in, it has been focusing on the research, development, production, and sales of high-quality, high-performance rubber and plastic environmental protection automation equipment. for more than 43 years, have thousands of customer cases, welcome for factory inspection.

MOQ is 1 pcs.

Sample is available for customer to check the quality before bulk order.

Our factory mainly produces plastic granulator products (such as Plastic Shredder, plastic dryer, Plastic chiller, etc.), and we can also customize other types of products according to customer needs.

Yes, we provide Non-standard customization service. We have a professional R&D team and production equipment, and can design and manufacture products according to customer needs.

Our factory has advanced technical equipment and efficient production lines, which can meet the needs of large-scale production. You can consult us for the specific production capacity, and we will evaluate and arrange according to your needs.

We attach great importance to product quality, and our factory strictly abides by the relevant quality management system and has passed ISO certification. During the production process, we will conduct multiple quality inspections to ensure that the products meet or exceed customer requirements and standards.

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance against the copy of B/L.

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

The shredder phase helps to protect the granulator by reducing the load during regrind once it is pre-shredded. It is best to use a shredder for heavy duty materials at a high volume. Shredder type may vary depending on the material type (e.g. single-shaft vs. multi-shaft). Most shredders can be used inline for continuous shredding.

Keeping you granulators and shredders maintained is very important. Be sure to regularly sharpen and replace knives when necessary. Dull knives produce less quality regrind and increase vibrations, which may cause more frequent maintenance.

ORTUNE GLOBAL 500 CERTIFICATION

Rubber products produced using the ZAOGE Rubber Environmental Utilization System are sold in over 100 countries worldwide.