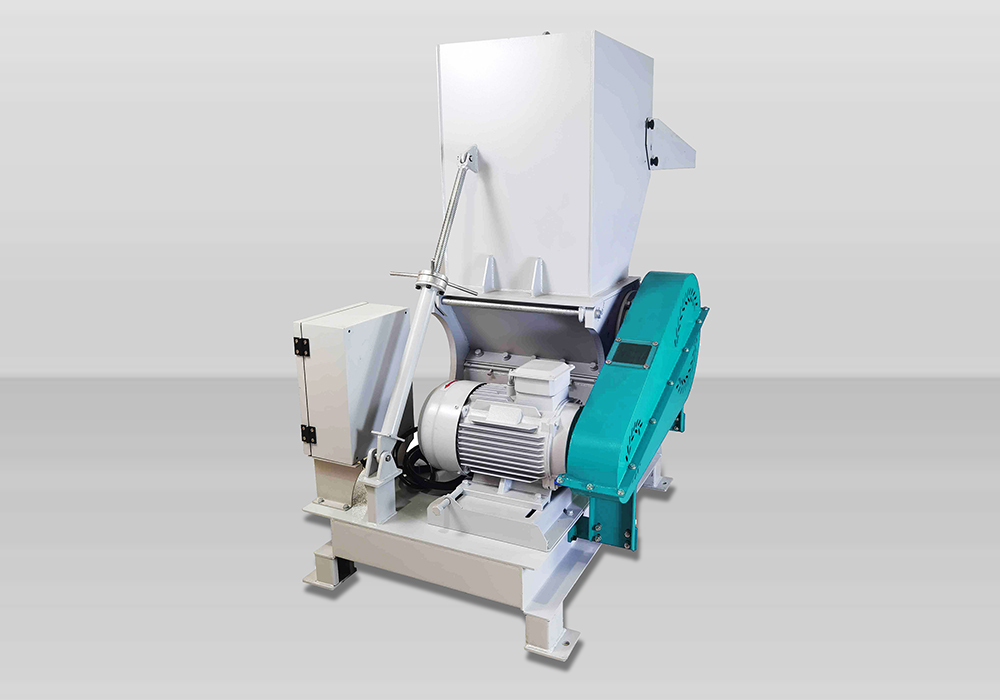

Claw Type Plastic Crusher machine

Description

The Claw-type Plastic Crusher is suitable for crushing and recycling various injections, blow molding defective products, or sprue materials.

The entire machine is made of high-quality steel, which is safe, sturdy, and durable. The cutting tools are made of SKD-11 material and can be adjusted telescopically. The special claw blade design makes crushing easier. An optional water circulation system is available to reduce heat during operation, preventing the agglomeration of crushed materials.

Description

The Claw-type Plastic Crusher is suitable for crushing and recycling various injection, blow molding defective products, or sprue materials.

The entire machine is made of high-quality steel, which is safe, sturdy, and durable. The cutting tools are made of SKD-11 material and can be adjusted telescopically. The special claw blade design makes crushing easier. An optional water circulation system is available to reduce heat during operation, preventing the agglomeration of crushed materials.

More Details

Crushing Chamber

The crushing chamber is made of strong and durable cast steel that is precisely machined using CNC technology. Its 30mm thickness guarantees a smooth surface that reduces friction and wear, resulting in a longer lifespan, higher efficiency, and safer operation.

Structure

The design of claw blades can improve cutting efficiency and reduce thermal deformation of materials. The blades are made of imported SKD-11 material, ensuring cutting efficiency, durability, and extended lifespan.

Structure

The design of claw blades can improve cutting efficiency and reduce thermal deformation of materials. The blades are made of imported SKD-11 material, ensuring cutting efficiency, durability, and extended lifespan.

Power System

Dongguan Motor is a good quality motor that is reliable, safe, and durable. It rarely breaks down, which ensures continuous and stable operation of the machine. It is also safe to use and lasts longer, which saves maintenance costs and reduces the need for part replacements.

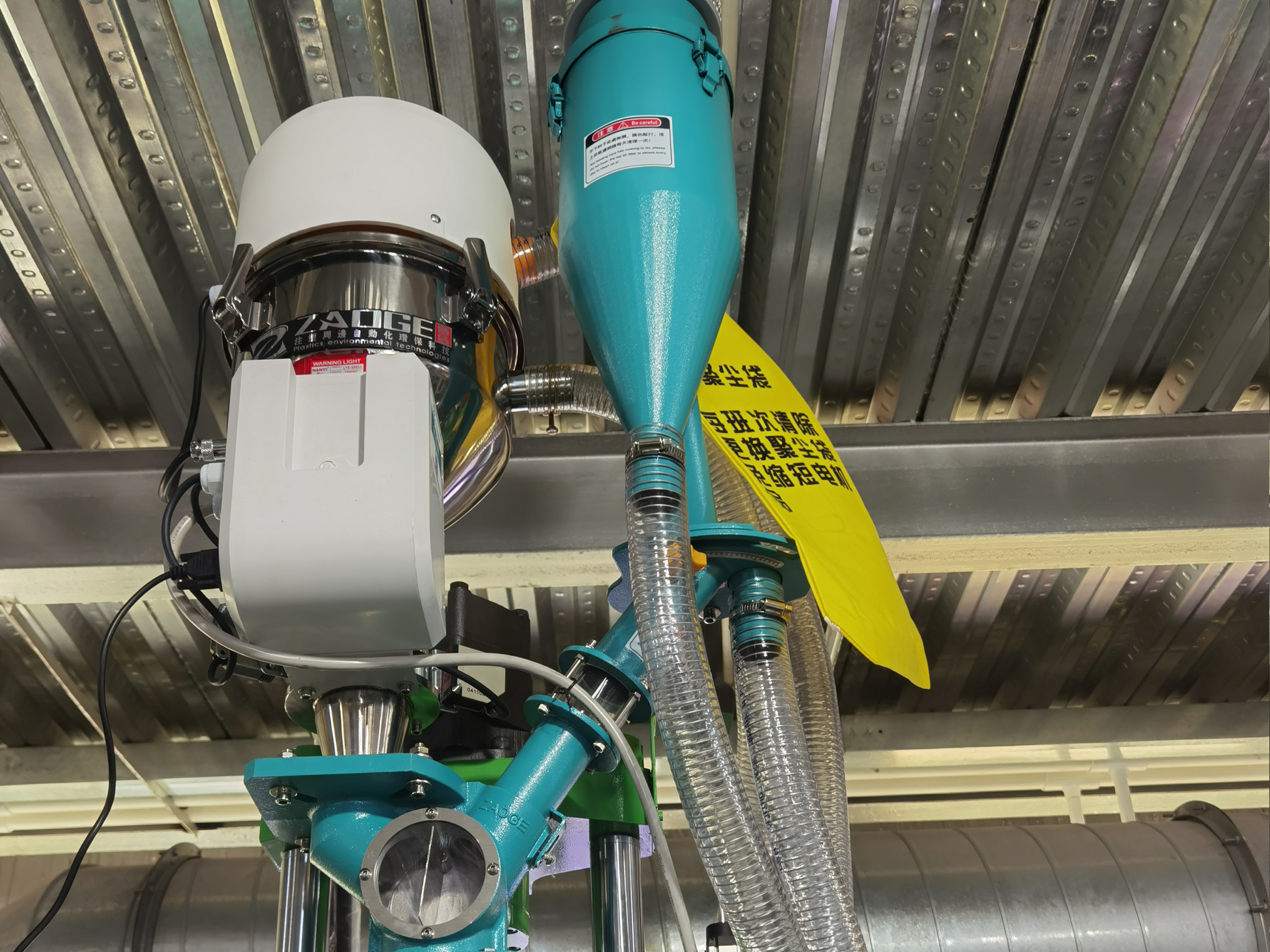

Control System

The control center is equipped with either Taiwan DYE or Schneider electric control system, which provides higher safety performance and better protection for both the machine and operators.

Control System

The control center is equipped with either Taiwan DYE or Schneider electric control system, which provides higher safety performance and better protection for both the machine and operators.

Plastic Crusher Applications

AC Power Supply Injection Molding

Automotive Parts Injection Molding

Silicone Rubber Material

Medical Injection Molded Products

Injection Molded for Helmets and Suitcases

Communications Electronics Products

Cosmetic Bottleswatering Cansplastic Condiment Bottles

Household Electrical Appliances

Specifications

|

ZGL series |

|||

|

Mode |

ZGL-615 |

ZGL-620 |

ZGL-630 |

|

Motor Power |

11KW |

15KW |

22KW |

|

Raotating Speed |

540rpm |

540rpm |

540rpm |

|

Fixed blades |

2*2PCS |

2*2PCS |

2*2PCS |

|

Rotating blades |

3*7PCS |

3*8PCS |

3*11PCS |

|

Cutting Chamber |

420*270*Φ300 |

480*340*Φ350 |

660*400*Φ380 |

|

Screen |

Φ8 |

Φ10 |

Φ10 |

|

Capacity |

300-500Kg/h |

350-550Kg/h |

500-800Kg/h |

|

Weight |

800Kg |

1200Kg |

1500Kg |

|

Dimensions L*W*H mm |

1320*900*1540 |

1560*960*1850 |

1700*1200*1900 |