It is difficult for an injection molding factory to make money, first of all because you have no bargaining power with suppliers.

The most important cost of an injection molded product is composed of six major components: electricity, personnel wages, plastic raw materials, equipment depreciation, mold depreciation, and factory rent. The corresponding suppliers are the State Grid, workers, plastic raw material manufacturers, injection molding equipment manufacturers, mold providers, and factory landlords.

These six points are explained in turn as follows:

First, State Grid

The State Grid is a monopoly, and as long as it supplies power to you, it will be good. If you want it to be more convenient for you in terms of uninterruptible power supply and transformer expansion, then you have to take care of it. The bargaining space for this item is 0.

Second, workers

You can reduce costs by reducing employee wages, but this will lead to staff attrition, the inability to find good talents, and greater hidden losses. In the injection molding factory, the temperature reaches over 40 degrees in the summer, and the working environment is harsh. Workers do part-time jobs and would rather work in an electronics factory with air conditioning and constant temperature. Therefore, wages cannot be lower than the industry average or the level of surrounding companies.This bargaining space is narrow.

Third, plastic raw material manufacturers

Basic raw materials are purchased from petrochemical plants, and modified raw materials are purchased from modified raw material plants. The basic materials for the modified raw material factory are also purchased from petrochemical plants, and they only earn a processing fee. Therefore, buying from modified raw material factories is equivalent to indirect supply from petrochemical plants. Is there room for negotiation with petrochemical plants? The petrochemical plants are all world giants. How can you negotiate with PetroChina and Sinopec?There is basically no room for negotiation on this item.

Fourth, injection molding equipment manufacturers

Among injection molding equipment, the injection molding machine is the main machine and the big head. Injection molding machine manufacturers are usually larger than injection molding plants. Injection molding machine manufacturers with an annual output value of more than 100 million yuan are very common, while injection molding machine manufacturers with an annual output value of less than 30 million yuan can only be regarded as workshops. But an injection molding factory has a scale if it reaches an annual output value of 30 million.

Therefore, the injection molding factory is also the younger brother in front of the injection molding machine factory and is also a vulnerable group. If you want to buy a branded molding machine, the other party is also a big company, often either a listed company or a multinational company, so it is difficult to have much space. Moreover, the depreciation of injection molding equipment in eight or ten years accounts for a small proportion of the injection molded products.

There is some room for negotiation, but it is very weakly reflected in product costs.

Fifth, mold provider

There are three sources of molds: (1) provided by customers; (2) provided by external mold suppliers; (3) provided by our own internal mold department.

In case (1), costs are not included and there is no negotiation issue. Case (2) has room for negotiation. Case (3) is the same as Case (2).

Sixth, factory landlord

The factory rental market is a seller's market. The main cost of a factory is land. Land is a non-renewable resource that cannot be supplied in unlimited quantities and is scarce. There is little room for negotiation in this area.

In front of customers, you are a vulnerable group; in front of suppliers, you are also a vulnerable group.

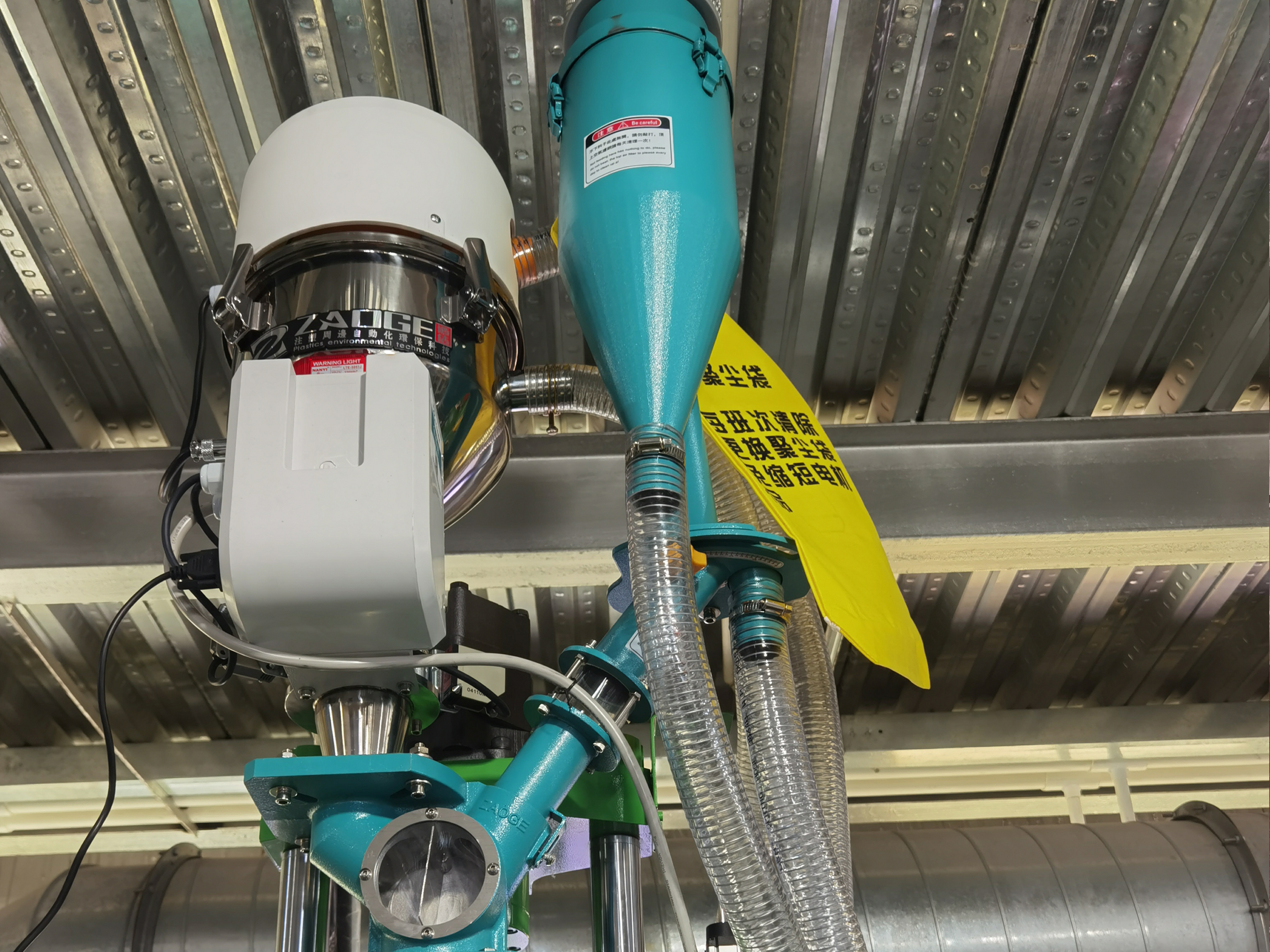

At this time, you have to figure out how to reduce the cost of purchasing raw materials. Leave it to the ZAOGE recycling grinder. Help you save 20%-30% of raw material costs. The 20%-30% saving in raw material costs is your profit.

ZAOGE online instant grinding and instant utilizing the hot waste items from the injection molding machine. The grinding material is uniform, clean, dust-free and pollution-free, and the quality of the product is higher.

Post time: May-22-2024