(1) Improper equipment selection. When selecting equipment, the maximum injection volume of the injection molding machine must be greater than the total weight of the plastic part and the nozzle, and the total injection weight cannot exceed 85% of the plasticizing volume of the injection molding machine.

(2) Insufficient feed. The commonly used method for controlling feed is the fixed volume feed method. The roller feed volume and the particle size of the raw material are uniform, and whether there is a “bridge” phenomenon at the bottom of the feed port. If the temperature at the feed port is too high, it will also cause poor material drop. In this regard, the feed port should be unblocked and cooled.

(3) Poor material fluidity. When the raw material fluidity is poor, the structural parameters of the mold are the main reason for insufficient injection. Therefore, the stagnation defects of the mold casting system should be improved, such as reasonably setting the runner position, expanding the gate, runner and injection port size, and using a larger nozzle. At the same time, an appropriate amount of additives can be added to the raw material formula to improve the flow properties of the resin. In addition, it is also necessary to check whether the recycled material in the raw material is excessive and appropriately reduce its amount.

(4) Excessive lubricant. If the amount of lubricant in the raw material formula is too much, and the wear gap between the injection screw check ring and the barrel is large, the molten material will flow back severely in the barrel, causing insufficient feeding and resulting in under-injection. In this regard, the amount of lubricant should be reduced, the gap between the barrel and the injection screw and the check ring should be adjusted, and the equipment should be repaired.

(5) Cold material impurities block the material channel. When impurities in the molten material block the nozzle or cold material blocks the gate and runner, the nozzle should be removed and cleaned or the cold material hole and runner section of the mold should be expanded.

(6) Unreasonable design of the pouring system. When a mold has multiple cavities, the appearance defects of the plastic parts are often caused by unreasonable design of the gate and runner balance. When designing the pouring system, pay attention to the gate balance. The weight of the plastic parts in each cavity should be proportional to the gate size so that each cavity can be filled at the same time. The gate position should be selected at the thick wall. A design scheme of split runner balance layout can also be adopted. If the gate or runner is small, thin, and long, the pressure of the molten material will be lost too much along the flow process, the flow will be blocked, and poor filling is likely to occur. In this regard, the flow channel cross section and gate area should be enlarged, and a multi-point feeding method can be used if necessary.

(7) Poor mold exhaust. When a large amount of gas remaining in the mold due to poor exhaust is squeezed by the material flow, generating a high pressure greater than the injection pressure, it will prevent the molten material from filling the cavity and cause under-injection. In this regard, it should be checked whether a cold material hole is set or whether its position is correct. For molds with deeper cavities, exhaust grooves or exhaust holes should be added to the under-injection part; on the mold surface, an exhaust groove with a depth of 0.02~0.04 mm and a width of 5~10 mm can be opened, and the exhaust hole should be set at the final filling point of the cavity.

When using raw materials with excessive moisture and volatile content, a large amount of gas will also be generated, resulting in poor mold exhaust. At this time, the raw materials should be dried and volatiles should be removed.

In addition, in terms of the process operation of the mold system, poor exhaust can be improved by increasing the mold temperature, reducing the injection speed, reducing the flow resistance of the pouring system, reducing the clamping force, and increasing the mold gap.

(8) The mold temperature is too low. After the molten material enters the low-temperature mold cavity, it will not be able to fill every corner of the cavity due to too fast cooling. Therefore, the mold must be preheated to the temperature required by the process before starting the machine. When the machine is just started, the amount of cooling water passing through the mold should be appropriately controlled. If the mold temperature cannot rise, the design of the mold cooling system should be checked to see if it is reasonable.

(9) The melt temperature is too low. Usually, within the range suitable for molding, the material temperature and the filling length are close to a positive proportional relationship. The flow performance of the low-temperature melt decreases, which shortens the filling length. When the material temperature is lower than the temperature required by the process, check whether the barrel feeder is intact and try to increase the barrel temperature.

When the machine is just started, the barrel temperature is always lower than the temperature indicated by the barrel heater instrument. It should be noted that after the barrel is heated to the instrument temperature, it still needs to be cooled for a period of time before the machine can be started.

If low-temperature injection is necessary to prevent the decomposition of the molten material, the injection cycle time can be appropriately extended to overcome under-injection. For screw injection molding machines, the temperature of the front section of the barrel can be appropriately increased.

(10) The nozzle temperature is too low. During the injection process, the nozzle is in contact with the mold. Since the mold temperature is generally lower than the nozzle temperature and the temperature difference is large, frequent contact between the two will cause the nozzle temperature to drop, resulting in the molten material freezing at the nozzle.

If there is no cold material hole in the mold structure, the cold material will solidify immediately after entering the cavity, so that the hot melt behind cannot fill the cavity. Therefore, the nozzle should be separated from the mold when opening the mold to reduce the impact of the mold temperature on the nozzle temperature and keep the temperature at the nozzle within the range required by the process.

If the nozzle temperature is very low and cannot be raised, check whether the nozzle heater is damaged and try to increase the nozzle temperature. Otherwise, the pressure loss of the flow material is too large and will cause under-injection.

(11) Insufficient injection pressure or holding pressure. The injection pressure is close to a positive proportional relationship with the filling length. If the injection pressure is too small, the filling length is short and the cavity is not fully filled. In this case, the injection pressure can be increased by slowing down the injection forward speed and appropriately extending the injection time.

If the injection pressure cannot be further increased, it can be remedied by increasing the material temperature, reducing the melt viscosity, and improving the melt flow performance. It is worth noting that if the material temperature is too high, the molten material will be thermally decomposed, affecting the performance of the plastic part.

In addition, if the holding time is too short, it will also lead to insufficient filling. Therefore, the holding time should be controlled within an appropriate range, but it should be noted that too long a holding time will also cause other faults. During molding, it should be adjusted according to the specific situation of the plastic part.

(12) The injection speed is too slow. The injection speed is directly related to the filling speed. If the injection speed is too slow, the molten material fills the mold slowly, and the low-speed flowing molten material is easy to cool, which further reduces its flow performance and causes under-injection.

In this regard, the injection speed should be appropriately increased. However, it should be noted that if the injection speed is too fast, it is easy to cause other molding faults.

(13) The structural design of the plastic part is unreasonable. When the thickness of the plastic part is not proportional to the length, the shape is very complex and the molding area is large, the molten material is easily blocked at the entrance of the thin-walled part of the plastic part, making it difficult to fill the cavity. Therefore, when designing the shape structure of the plastic part, it should be noted that the thickness of the plastic part is related to the limit flow length of the molten material during mold filling.

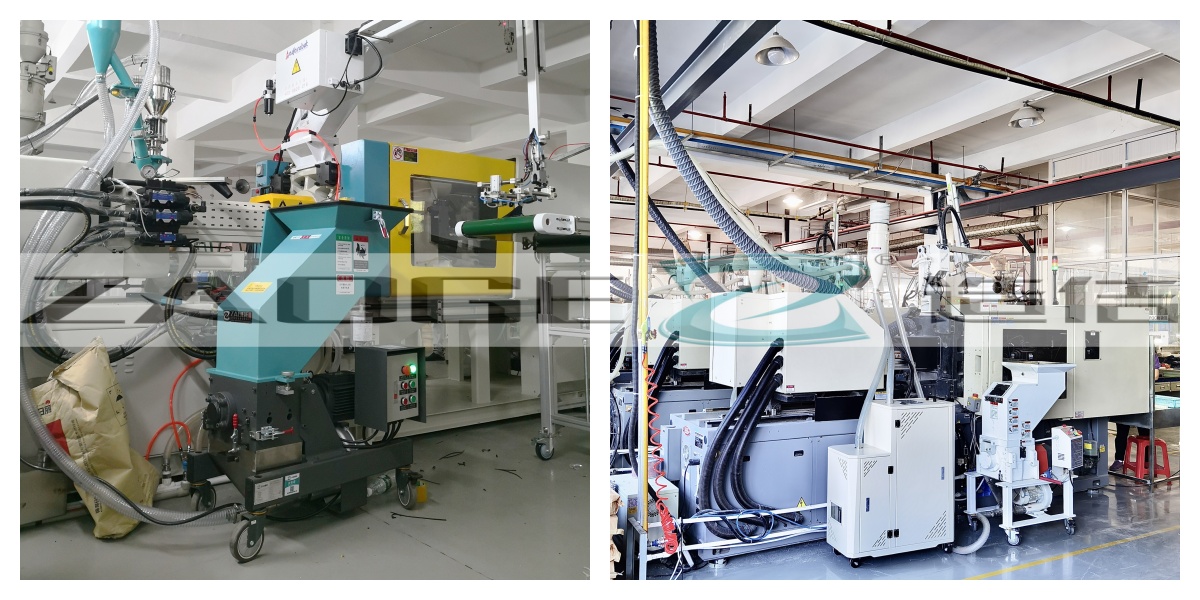

So how can we simply and effectively recycle the runner material produced by the injection molding machine? ZAOGE’s patented inline instant hot crushing and high quality instant recycling solution. To better control the product quality and price. Those crushed materials are uniform, clean, dust-free, pollution-free, high quality, mixed with raw materials to produce products of high quality.

Post time: Jul-10-2024