Part 1: Functions and qdvantages of plastic shredder

Plastic shredder is a piece of equipment specially used to break waste plastic products into small particles. Its function is to reprocess and reuse plastic waste, reduce the accumulation of waste, and at the same time create economic benefits for enterprises. The advantages of plastic shredders are high efficiency, energy saving and reliability, and can process many types of plastic products, such as bottles, films and containers.

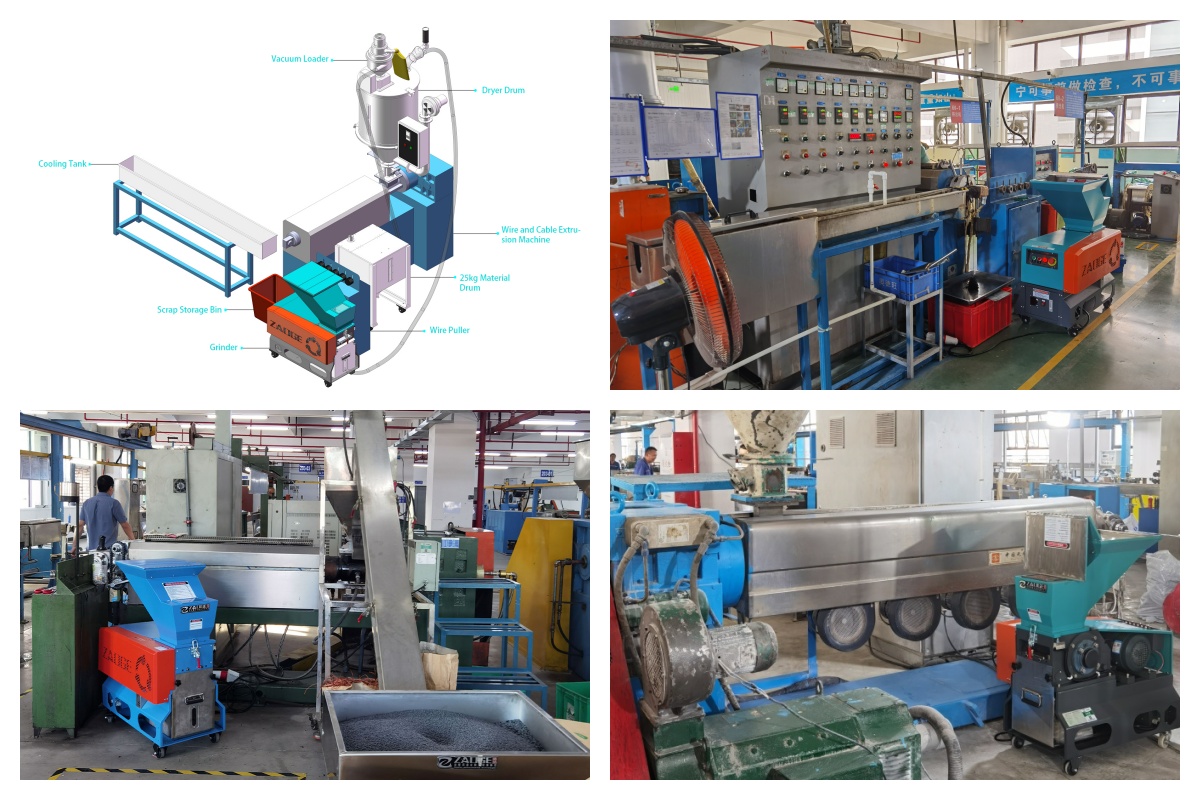

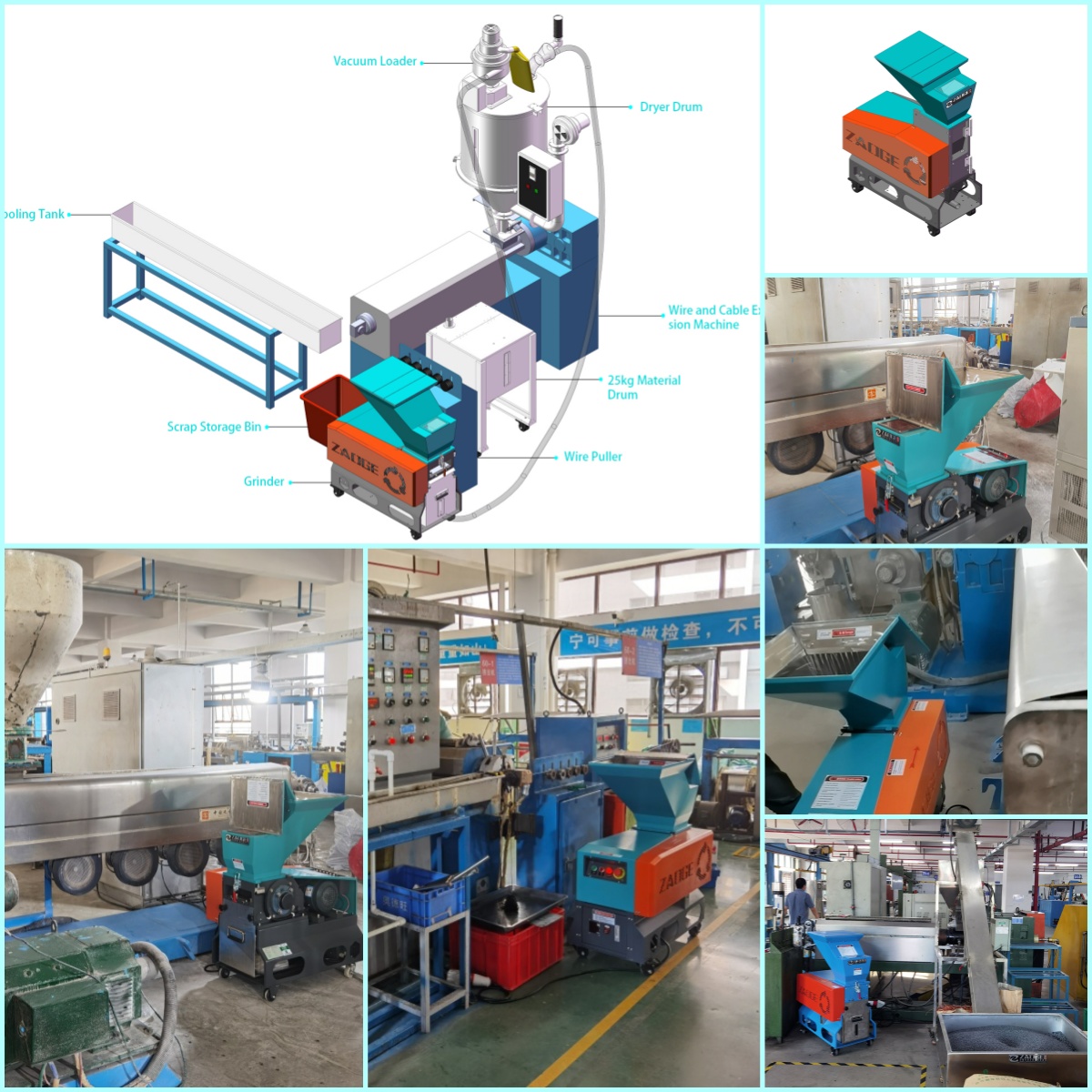

Part 2: Functions and advantages of cable extruders

A cable extruder is a device used to heat and melt plastic particles and then extrude them into cables. Its function is to process plastic particles into various specifications and types of cables for use in fields such as power transmission and communications. The advantages of cable extruders are high efficiency, precision and controllability, enabling precise control of cable diameter, insulation layer thickness and appearance quality.

Part 3: Cooperative application of plastic shredder and cable extruder

By using plastic shredders and cable extruders in conjunction with each other, synergy can be achieved to maximize benefits. Here are some specific ways to use collaboration:

Plastic waste recycling: Plastic shredder breaks waste plastic products into small particles, which can be directly used as raw materials for cable extruders to produce cables. By recycling and reusing waste, companies can reduce raw material procurement costs and reduce production costs while having a positive impact on the environment.

Plastic coating preparation: Plastic shredder can break plastic waste into particles, and then these particles can be extruded into plastic coating through cable extruder. This coating can be used as the insulation or sheath layer of a cable to provide insulation and protection to the cable. In this way, companies can reuse waste materials while improving the quality and performance of the cables.

Special function cable manufacturing: Plastic shredder can process different types of plastic waste and break it into particles. These granules can be combined with other additives or fillers to produce cables with special functions through a cable extruder. For example, adding fire-resistant agents can produce flame-retardant cables, and adding anti-UV agents can produce anti-aging cables for outdoor use. In this way, companies can develop cable products with specific functions and market competitiveness.

In conclusion:

The coordinated application of plastic shredders and cable extruders can bring many advantages to maximize benefits. Through the recycling and reuse of plastic waste, companies can reduce raw material procurement costs, reduce waste accumulation, and have a positive impact on the environment. At the same time, by combining the plastic shredder with the cable extruder, high-quality cable products can be produced, including cables with special functions. This not only improves the competitiveness of the product, but also expands the market potential.

Post time: Apr-08-2024