When dealing with clean plastic waste, effective recycling methods can include the following:

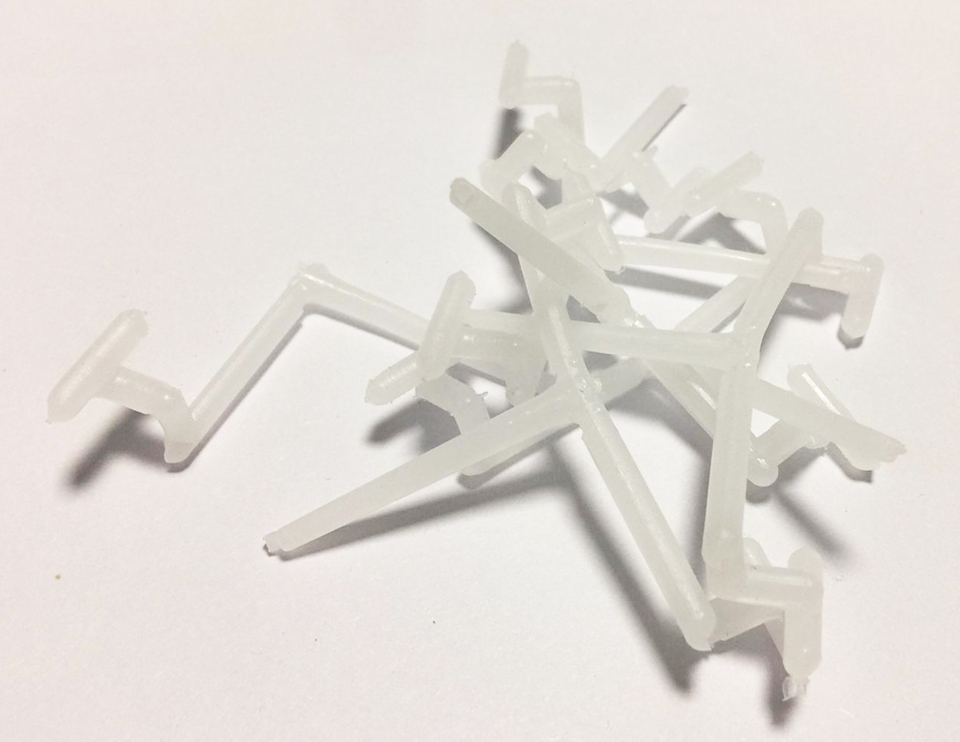

Mechanical recycling: Feed clean plastic waste into specialized recycled plastic processing equipment, such as shredders, crushers, pellet machines, to process it into recycled plastic pellets or pellets. These recycled plastic particles can be used to make new plastic products, such as containers, pipes, sheets, etc.

Thermoforming Recycling: Certain types of clean plastic waste can be recycled through thermoforming technology. In this method, plastic waste is heated to a molten state and then shaped into new plastic products through a mold or extruder.

Chemical recycling: Clean plastic waste can sometimes be recycled through chemical methods, such as converting it into raw materials or chemicals. This often requires specialized equipment and technology, but allows for efficient plastic waste conversion.

Physical recycling: In addition to mechanical methods, physical methods such as gravity sorting, air flow sorting, etc. can also be used for effective recycling of plastic waste. These methods can separate and classify plastics based on their density, size and other physical properties.

Recycling into raw materials: Using clean plastic waste as raw materials to participate in the mixing and production of new plastic products is a common recycling method. In this approach, plastic waste can be blended with new raw materials, lowering production costs and reducing resource consumption.

The choice of recycling treatment method depends on factors such as the type, size, cost and feasibility of the waste. The best approach may be to use a combination of technologies and methods to maximize the recycling rate and reuse value of plastic waste.

ZAOGE is able to offer scientific solutions of clean plastic waste processes. Whether you are an injection molder, an extruder, blow molder, thermoformer, ZAOGE has auxiliary equipment solutions for you. If you consider yourself part of an end-market such as packaging, medical, building and construction, or any other, ZAOGE has specialized expertise to help you. No matter whether you are located in Unite State or India, Germany, Mexico,China, or even all of those places, ZAOGE is there to serve you.

ZAOGE manufacture plastic crushers, material-saving equipment for the plastic injection molding and extrusion industry,blow molder, thermoformer.

ZAOGE machines are designed to save materials, space, energy, time, low consumption and low carbon.

Post time: Apr-28-2024