When the sprue material produced by plastic injection molding is heated once, it will cause physical damage due to plasticization. Heating from normal temperature to high temperature, injection molding, the sprue material returns from high temperature to normal temperature. The physical properties begin to change. Generally speaking, it will take 2-3 hours for the physical properties to reach complete 100% destruction after one plasticization. The immediate crushing and recycling equipment is to take out the plastic sprue material at high temperature and immediately put it into the machine to crush, transport and sieve the powder, and use it immediately within 30 seconds at a certain ratio.

Characteristics of plastic sprue materials

In today’s era, business competition is fierce. Effective management and routine high-return profits are the goals pursued by every business owner. And “lowering costs and improving quality” is the only way to achieve sustainable operations. The biggest cost burden in the plastics manufacturing industry is the long-term purchase of plastic materials. Assuming that everyone purchases at the same price, then how to maximize its marginal benefits can reduce costs and improve competitiveness. Everyone knows this. The question is how to do it?

To put it simply: in the plastic manufacturing process, it can reduce the defective rate, increase output, effectively recycle defective products without affecting their quality, and achieve low carbon, environmental protection, and energy saving, and these operations can be completed automatically, then Becoming ideal.

The production of sprue materials has four characteristics: regularity, certainty, timing and quantification.

When it is produced, it should generally be clean and dry; it is not polluted and does not absorb moisture, so it has the conditions for immediate recycling, that is, the immediate recycling of thermoplastic plastic sprue materials came into being.

1. Characteristics of immediate recycling of plastic sprue materials

1.1. Four elements for immediate recycling of sprue materials

1) Clean: contaminated items cannot be recycled immediately. Generally speaking, when the sprue material is generated, it is the cleanest to put it into recycling immediately.

2) Drying: When the sprue material is taken out, it is immediately put into recovery to be hot and dry.

3) Fixed ratio:

The sprue material is 100% recycled and thrown in one at a time. Of course, the proportions of each mold are the same.

If 50% of the sprue material is recycled, the sprue material will be crushed immediately. The automatic recovery device has a selector valve for regulation.

4) Sieve powder: When fine dust enters the high-temperature Screw, it will be charred and carbonized, which will affect the physical properties, color, and gloss, so it must be screened out.

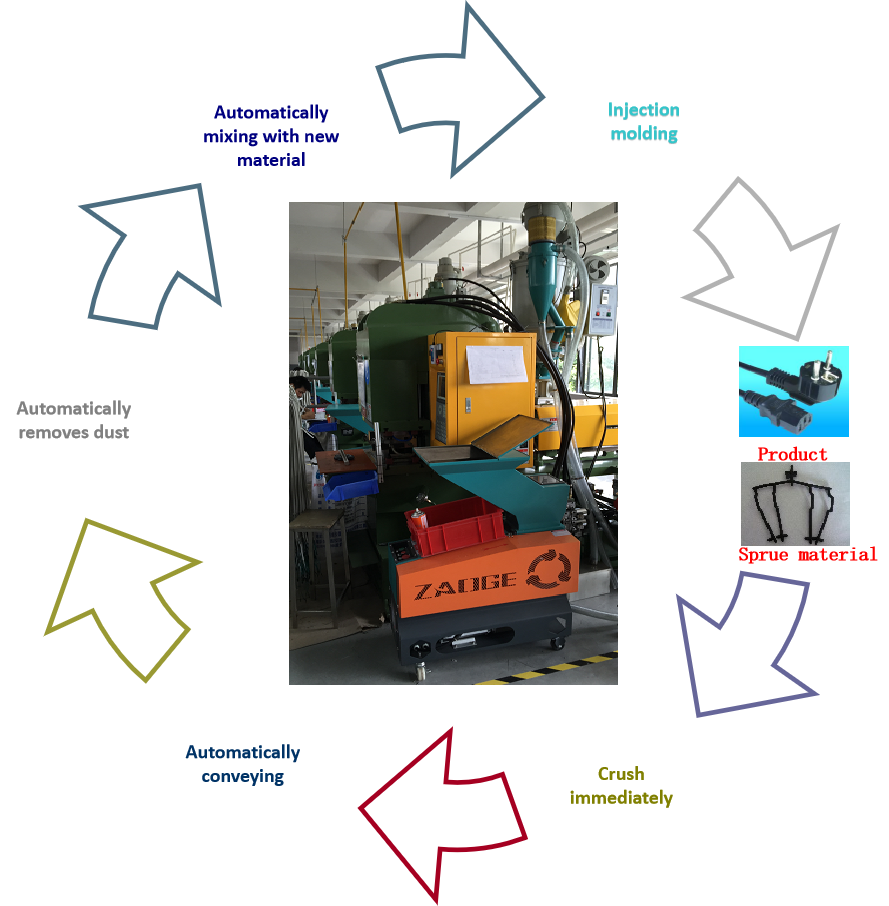

1.2. Flow chart for immediate crushing and recycling of plastic sprue materials:Shredding and recycling

The plastic sprue material is immediately crushed and recycled within 30 seconds, so that the sprue material will not be polluted by oxidation and humidification (absorption of water vapor in the air), which will cause the physical properties of the plastic – strength, stress, color and gloss to be damaged, thus improving the quality of the molded product. Quality; this is the main value of this “Equipment for Immediate Recycling“. And it can reduce the waste and loss of plastic, labor, management, warehousing, and purchasing materials. Reduce costs and improve quality to ensure sustainable business operations.

ZAOGE plastic crusher for the plastic iniection molding and extrusion industry,blowmolder, thermoformer.

Post time: May-05-2024