Selecting the right plastic shredder is crucial for optimizing your recycling process. Here are some key factors to consider, backed by expert advice from ZAOGE:

1. Material Type Matters

The type of plastic you plan to shred is the most important factor. Different plastics require different shredding techniques:

Rigid Plastics: Hard plastics like PVC and polystyrene are tough and best suited for compression or impact shredders.

Flexible Plastics: Softer, tougher plastics such as nylon and ABS require shear shredders for effective processing.

2. Shredding Capacity

The size, hardness, and toughness of the plastics will dictate the shredding capacity you need. Generally, a higher motor power means greater shredding ability, but it also leads to increased energy consumption.

3. Screen Size

The screen hole size is another critical consideration. Smaller holes yield finer plastic particles, but may slow down the output speed. Choose a screen size that aligns with your specific needs.

4. Brand and Quality

The brand and quality of the equipment are vital. Reputable brands often provide better quality and customer support, along with longer warranties. ZAOGE, established in 1977 in Taiwan, has a longstanding reputation for high-quality, durable, and environmentally friendly plastic processing equipment.

5. Equipment Specifications and Models

Selecting the right specifications and models is essential. Different shredding applications and volumes require tailored machine types. For instance, if you need fine particle sizes, a machine with multi-stage shredding capabilities is ideal.

6. Safety Features

Don’t overlook safety. Choose shredders equipped with safety features such as automatic shutdown and overload protection to ensure a secure working environment.

7. Cost and Budget

Cost is always a consideration. Aim for the best value within your budget, balancing quality and price effectively.

8. Maintenance and Cleanliness

Machines that are easy to maintain and clean will save you time and costs in the long run. For example, the ZAOGE Silent Plastic Shredder features V-shaped cutting tools without screws and an open design that minimizes dead corners, resulting in low maintenance needs. It operates at just 30 decibels, reducing workplace noise pollution.

9. Level of Automation

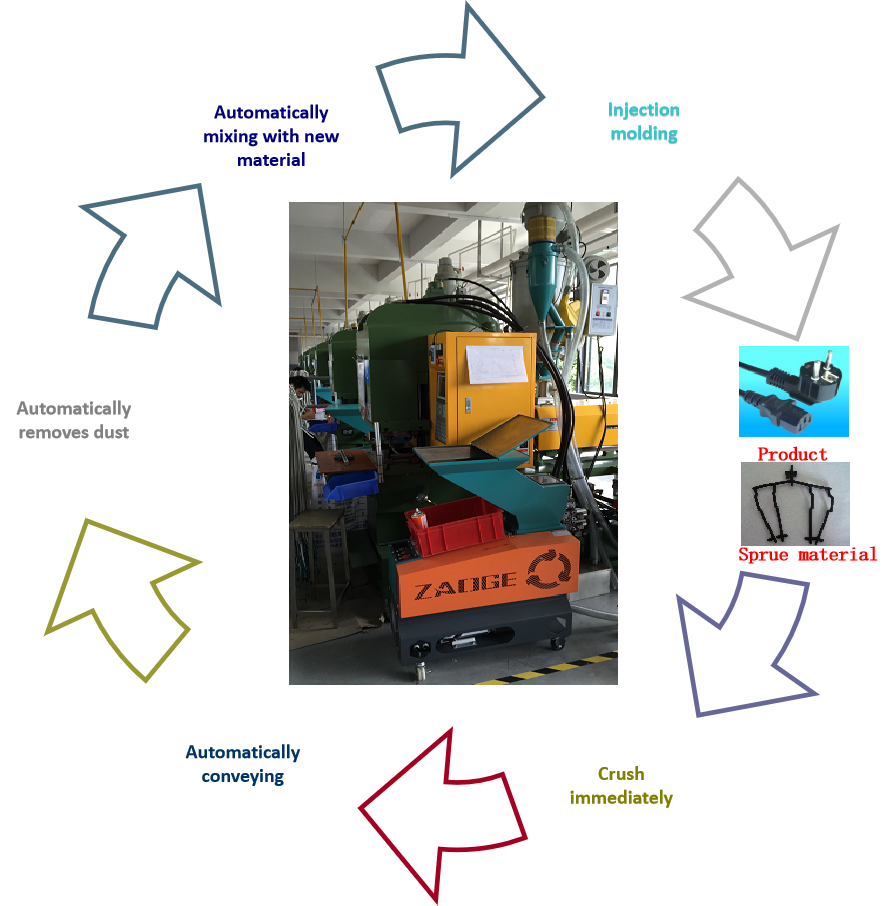

The degree of automation in a shredder can significantly impact production efficiency and labor intensity. Automated shredders can revolutionize your operations, making processes more efficient. ZAOGE offers a plastic crusher with an instant crushing and utilization system, along with drying and conveying equipment for customized needs.

Conclusion

When choosing a plastic shredder, consider material type, shredding capacity, screen size, brand quality, specifications, safety, cost, maintenance, and automation level. ZAOGE Plastic Shredder looks forward to partnering with you for a sustainable future. Let’s create a better tomorrow together!

Post time: Dec-03-2024