In the manufacturing of cables, industrial power strips, data cables, and other types of wiring, managing cable waste is crucial. Recovering copper from discarded cables not only reduces production costs but also effectively minimizes resource waste and environmental impact. Copper wire granulators, as essential equipment for cable waste recycling, have become a go-to solution for many manufacturers. So, how much copper can a granulator recover from one ton of cable waste? What are the economic benefits? Let’s explore these questions in detail.

1. How Copper Wire Granulators Work

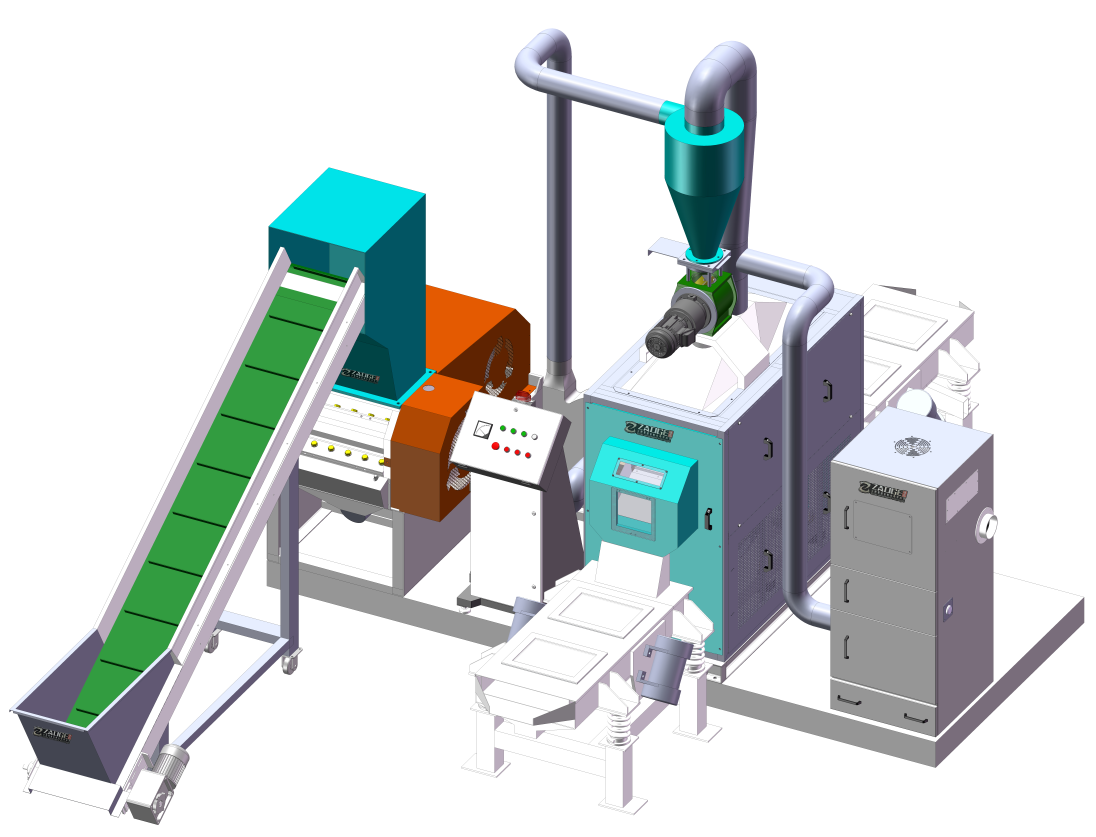

Copper wire granulators are designed specifically to recover copper from discarded cables. The primary principle is to effectively separate copper from plastic, resulting in high-purity copper granules. The processing steps involve crushing, screening, and electrostatic separation, ensuring high-purity copper recovery and preventing contamination of the separated plastic.

Take, for example, a granulator by ZAOGE, which achieves a separation accuracy of over 99%. This high accuracy makes it possible to efficiently recover copper from various types of cable waste, which can contain anywhere from 40% to 85% copper, depending on the type of cable—whether automotive, industrial, or household wiring. Therefore, the actual copper recovery from one ton of cable waste depends on the specific type of cable being processed.

2. Example Analysis: Copper Recovery from Different Types of Cable Waste

Let’s consider a manufacturer using a high-efficiency copper wire granulator to process two types of waste cables: automotive cable waste with relatively low copper content, and industrial cable waste with higher copper content.

Automotive Cable Waste: Approximately 50% copper content, yielding about 500 kg of copper per ton.

Industrial Cable Waste: Approximately 85% copper content, yielding about 850 kg of copper per ton.

Assuming the granulator processes 5 tons per day, it would yield 2.5 tons of copper from automotive cable waste and 4.25 tons from industrial cable waste. This shows how cable type greatly affects copper recovery, and why it is essential for companies to assess the composition of their cable waste and select suitable equipment and processing volumes accordingly.

3. Copper Market Prices and Recovery Benefits

Copper, as a critical industrial material, has a market price influenced by global supply and demand. For instance, at a current price of $8,000 per ton, recovering 850 kg of copper from industrial cable waste yields around $6,800 in revenue. At a processing capacity of 5 tons per day, this results in approximately $34,000 daily from copper recovery alone. Even when processing lower-copper automotive cables, daily copper recovery value can still reach about $20,000.

Additionally, copper wire granulators can recover the plastic in cable waste. Although plastic’s market price is lower, its effective separation and reuse still bring some added income. Considering the combined copper and plastic recovery, the return on investment for a copper granulator is relatively short, often achievable within 1 to 2 years.

4. Additional Benefits of Using Copper Wire Granulators

Reduced Raw Material Costs: By using a copper wire granulator, companies can extract high-purity copper from their internal waste, reducing dependence on external raw material purchases and saving on procurement costs.

Environmental Protection and Sustainable Resource Use: Copper wire granulators separate copper and plastic without secondary pollution, making the process environmentally friendly. This helps companies meet environmental responsibilities and comply with green production policies.

Enhanced Market Competitiveness: In a market with rising copper prices, companies with internal copper recovery capabilities have a price advantage and flexibility, enabling them to better handle raw material price fluctuations and improve market competitiveness.

5. Conclusion

Copper wire granulators can efficiently recover copper from cable waste while also allowing for the recycling of plastic. In the current market with high copper prices and strict environmental requirements, investing in a copper wire granulator is a smart choice for cable manufacturers and related industries. With ZAOGE’s high-separation granulators achieving over 99% accuracy, companies can significantly improve economic benefits and contribute to sustainable development.

If you need further information on specific models or processing capacities, contacting us. We hope this article assists cable manufacturers, power strip makers, data cable and wire manufacturers in making informed waste processing decisions.

Post time: Nov-11-2024