The car bumper is one of the larger decorative parts on the car. It has three main functions: safety, functionality and decoration.

Plastics are widely used in the automotive industry because of their light weight, good performance, simple manufacturing, corrosion resistance, impact resistance, and relatively large degree of design freedom, and they account for an increasing proportion of automotive materials. The amount of plastic used in a car has become one of the standards for measuring the development level of a country's automobile industry. At present, the plastic used to produce a car in developed countries has reached 200kg, accounting for about 20% of the mass of the entire vehicle.

Bumper materials usually have the following requirements: good impact resistance and good weather resistance. Good paint adhesion, good fluidity, good processing performance, and low price.

According to this, PP materials are undoubtedly the most cost-effective choice. PP material is a general-purpose plastic with relatively good performance. However, PP itself has poor low-temperature performance and impact resistance, is not wear-resistant, is easy to age, and has poor dimensional stability. Therefore, modified PP is usually used for automobile bumper production. Material. At present, special polypropylene automobile bumper materials are usually made of PP as the main material, and a certain proportion of rubber or elastomer, inorganic filler, color masterbatch, additives and other materials are added through mixing and processing.

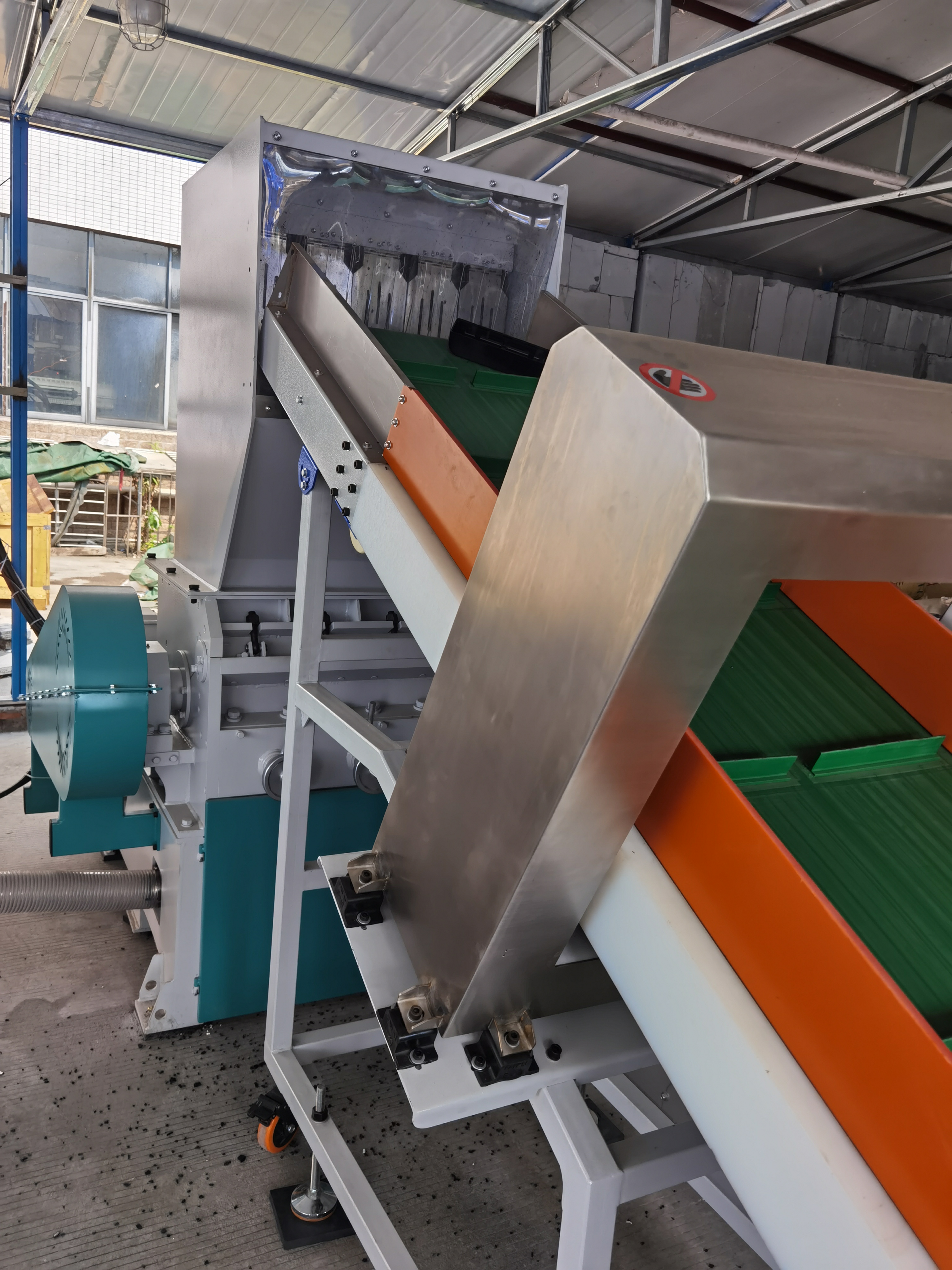

So how to deal with the sprue materials, runner materials and defective products produced during the injection molding process of automobile plastic bumpers? Leave it to ZAOGE energy-saving and material-saving recycling machine. After the sprue material and runner material are hot crushed by plastic crusher, they can be added to new materials to inject products together. Defective products can be crushed in a centralized manner and processed into materials for secondary processing and then injection molded.

Post time: May-09-2024