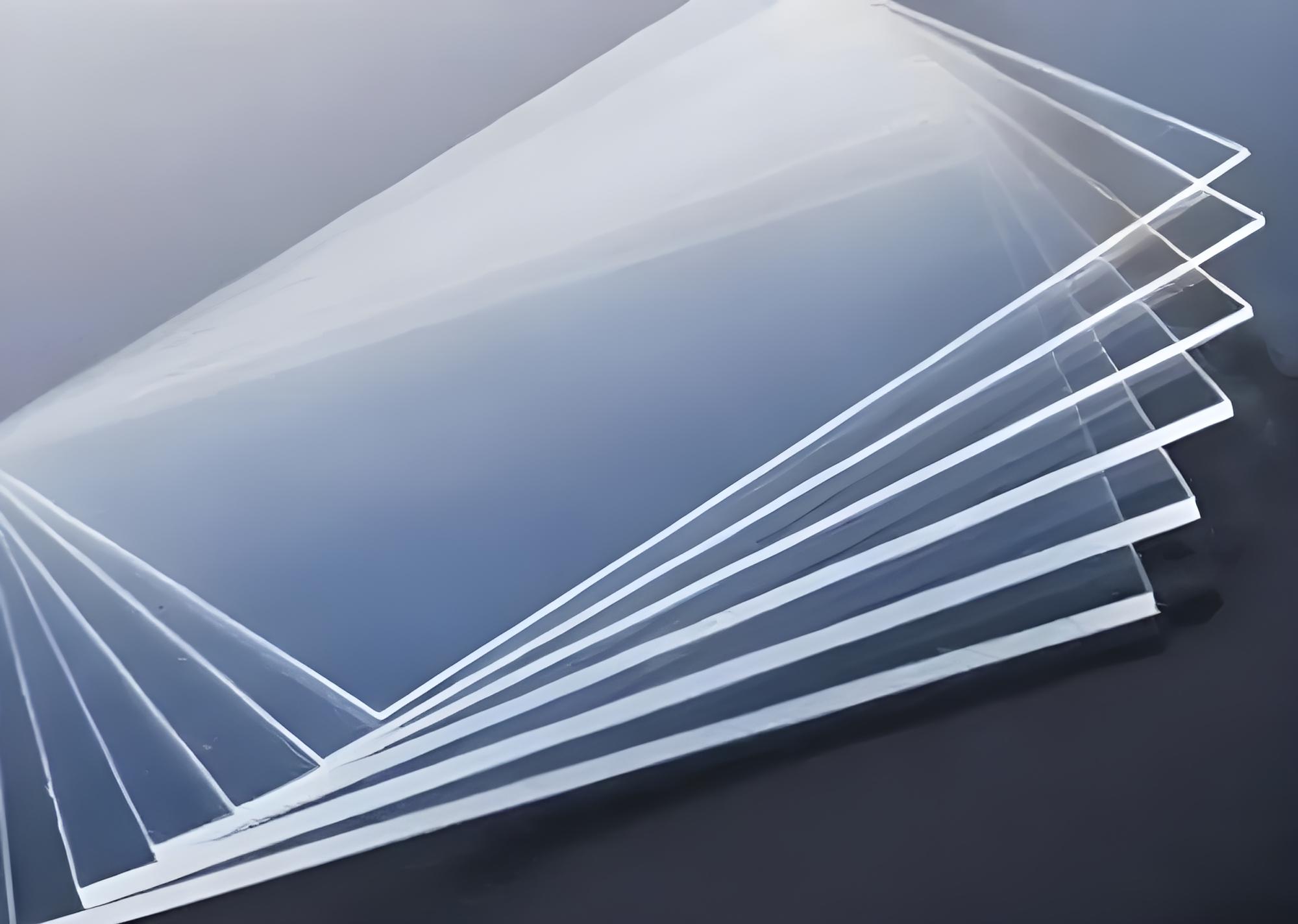

The chemical name of acrylic is polymethylmethacrylate (PMMA in English). Due to the shortcomings of PMMA such as low surface hardness, easy rubbing, low impact resistance, and poor molding flow performance, modifications of PMMA have appeared one after another. Such as the copolymerization of methyl methacrylate with styrene and butadiene, the blending of PMMA and PC, etc.

The flow behavior of PMMA is worse than that of PS and ABS, and the melt viscosity is more sensitive to temperature changes. During the molding process, the melt viscosity is mainly changed based on the injection temperature. PMMA is an amorphous polymer with a melting temperature greater than 160°C and a decomposition temperature of 270°C.

1. Disposal of plastics

PMMA has a certain degree of water absorption, with a water absorption rate of 0.3-0.4%. Injection molding requires a humidity below 0.1%, usually 0.04%. The presence of moisture causes bubbles, air streaks, and reduced transparency in the melt. So it needs to be dried. The drying temperature is 80-90℃ and the drying time is more than 3 hours. Recycled materials can be 100% used in some cases. The actual amount depends on the quality requirements, usually more than 30%. Recycled materials must be avoided from contamination, otherwise it will affect the transparency and properties of the finished product.

2. Selection of injection molding machine

PMMA has no special requirements for injection molding machines. Because of its high melt viscosity, it requires a deeper groove and a larger diameter nozzle hole. If the strength requirements of the product are higher, a screw with a larger aspect ratio should be used for low-temperature plasticization. In addition, PMMA must be stored in a dry hopper.

3. Mold and gate design

The mold temperature can be 60℃-80℃. The diameter of the main channel should match the internal taper. The optimal angle is 5° to 7°. If you want to injection mold 4mm or above products, the angle should be 7° and the diameter of the main channel should be 8 to 8°. 10mm, the overall length of the gate should not exceed 50mm. For products with wall thickness less than 4mm, the flow channel diameter should be 6-8mm

For products with a wall thickness greater than 4mm, the diameter of the runner should be 8-12mm. The depth of the diagonal, fan-shaped and vertical slice gates should be 0.7 to 0.9t (t is the wall thickness of the product). The diameter of the needle gate should be 0.8 to 2mm; the smaller size should be chosen for low viscosity.

Common vent holes are within 0.05 deep, 6 mm wide, and the draft angle is between 30′-1° and the cavity part is between 35′-1°30°.

4. Melt temperature

It can be measured by the in-air injection method: ranging from 210℃ to 270℃, depending on the information provided by the supplier.

Exit the back seat, make the injection molding machine nozzle leave the main channel bushing, and then manually perform plastic injection molding, which is air injection molding.

5. Injection temperature

Fast injection can be used, but to avoid high internal stress, it is better to use multi-stage injection, such as slow-fast-slow, etc. When injecting thick parts, use slow speed.

6. Residence time

If the temperature is 260°C, the residence time cannot exceed 10 minutes. If the temperature is 270°C, the residence time cannot exceed 8 minutes.

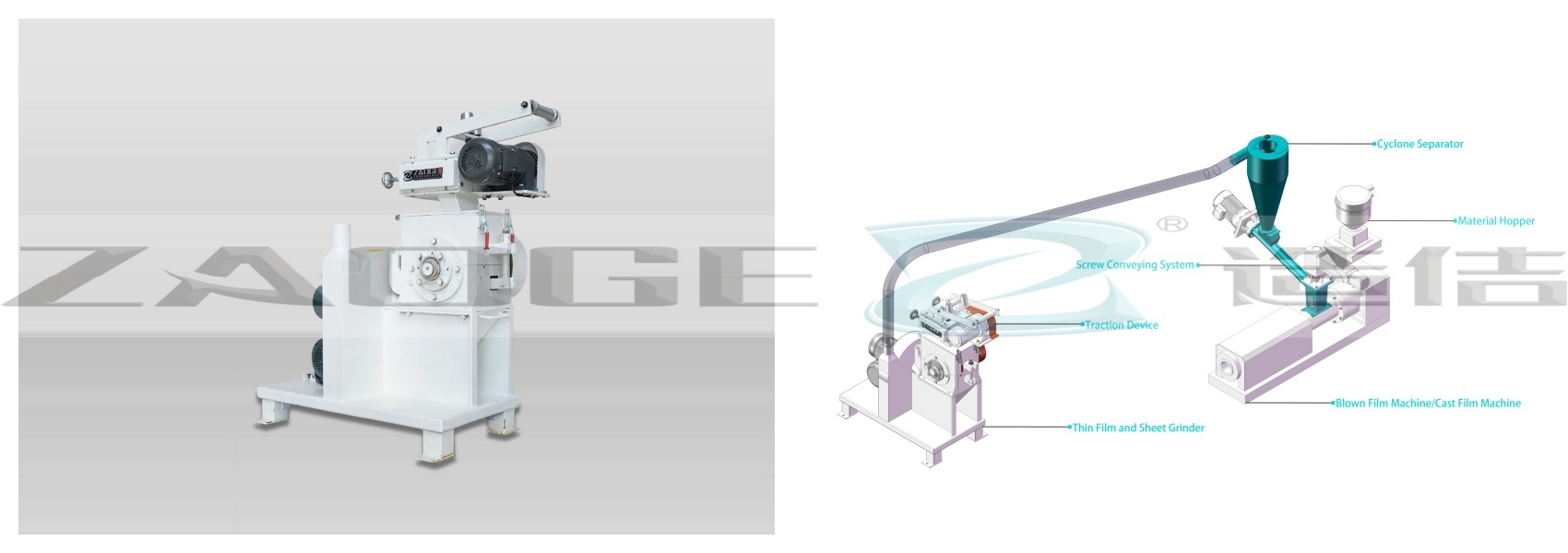

ZAOGE Film Crusher is suitable for crush various soft and hard edge scrap materials with a thickness of 0.02~5MM, such as PP/PE/PVC/PS/GPPS/PMMA films, sheets, and plates used in stationery, packaging, and other industries.

It can be used to collect, crush and convey the edge scrap materials produced by extruders, laminators, sheet machines, and plate machines. For example, the crushed materials are transported by a conveying fan through a pipeline to a cyclone separator, and then pushed into the extruder screw feed port by a feeding screw for automatic mixing with new materials, thus achieving instant environmental protection and utilization.

Post time: Jul-01-2024